1. What is vegetal chitosan?

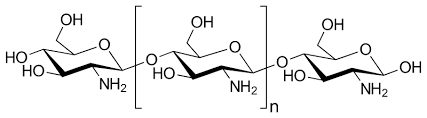

Chitosan is a natural biopolymer that is primarily derived from chitin, which is the second most abundant natural polysaccharide after cellulose. Chitin is commonly found in the exoskeletons of crustaceans like crabs, shrimps, and lobsters, as well as in the cell walls of certain fungi like mushroom, aspergillus niger.

Structure and Properties:

- Chemical Structure: Chitosan is obtained by deacetylating chitin. This process involves removing acetyl groups from chitin, resulting in a polymer that has free amine groups.

- Solubility: Unlike chitin, chitosan is soluble in acidic to neutral solutions, making it more versatile for various applications.

- Biocompatibility and Biodegradability: Chitosan is known for its excellent biocompatibility and biodegradability. It’s non-toxic and can be broken down by natural biological processes.

Chitosan, sometimes known as deacetylated chitin, is a natural polycationic linear polysaccharide derived from partial deacetylation of chitin. Chitin is the structural element in the exoskeleton of insects, crustaceans (mainly shrimps and crabs shell), and cell walls of fungi (oyster mushroom, agaricus bisprous and aspergillus niger), and also is the second most abundant natural polysaccharide after cellulose.

Chitosan, a natural polysaccharide prepared of fungal origin, is initially extracted and purified from reliable and abundant food or biotechnological fungal sources such as Agaricus bisporus or Aspergillus niger.

Chitosan is composed of glucosamine sugar units (deacetylated units) and N-acetyl-D-glucosamine units (acetylated units) interconnected by ß→(1.4) type linkages.

Uses and Applications:

- Medical and Pharmaceutical Fields: Due to its biocompatibility and non-toxic nature, chitosan is used in wound healing, drug delivery systems, and as a biomaterial in tissue engineering.

- Water Treatment: Its ability to bind with heavy metals and other contaminants makes it useful in water purification and treatment processes.

- Agriculture: As a natural biostimulant and elicitor, chitosan is used to enhance plant growth and provide resistance against pathogens.

- Food Industry: It’s used as a food additive for its antimicrobial properties, and as an edible film or coating to enhance the shelf life of perishable food products.

- Cosmetics and Personal Care: In this realm, it finds use as a thickener, moisturizer, and film-forming agent, particularly in hair and skin care products.

Chitosan has been widely used in various fields, including wine, pharmaceuticals, dietary supplement, medicine, agriculture, and food industries, due to its biocompatibility, biodegradability, and non-toxicity. In recent years, researchers have investigated the use of vegetal chitosan, which is derived from fungal or plant sources, as a sustainable alternative for use in wine applications.

Variants:

- Traditional Chitosan: Traditionally sourced from marine crustaceans.

- Vegetal Chitosan: Derived from fungal sources, offering an alternative for those seeking non-animal derived products.

In summary, chitosan’s versatility, biodegradability, and non-toxic nature make it a valuable material across various industries, from healthcare to cosmetics. Its ability to be derived from non-animal sources also makes it an appealing option for vegetarian and vegan-friendly products.

2. What are the advantages of vegetal chitosan?

Vegetal chitosan, also known as fungal chitosan or mycelium chitosan, is a type of chitosan derived from the cell walls of fungi (mushroom and aspergillu niger). It has several advantages over traditional chitosan derived from shellfish, including:

- 1. Vegan and vegetarian-friendly: Vegetal chitosan is an excellent alternative for individuals who avoid animal-based products, such as those who follow a vegan or vegetarian lifestyle.

- 2. Allergen-free: Traditional chitosan is derived from shellfish, which can cause allergic reactions in some people. Vegetal chitosan does not contain any shellfish-derived ingredients, making it an allergen-free option.

- 3. Purer: Vegetal chitosan is often considered to be purer than traditional chitosan because it is derived from a single source, whereas traditional chitosan can be contaminated with other shellfish-related substances.

- 4. Better solubility: Vegetal chitosan is more soluble than traditional chitosan, which makes it easier to incorporate into various applications such as cosmetics, pharmaceuticals, wine and food.

- 5. Improved bioavailability: Some studies have suggested that vegetal chitosan has a higher bioavailability compared to traditional chitosan, which means that it can be absorbed and utilized more effectively by the body.

Overall, vegetal chitosan offers several advantages over traditional chitosan, making it an attractive alternative for individuals and industries looking for a vegan, allergen-free, and more effective chitosan source.

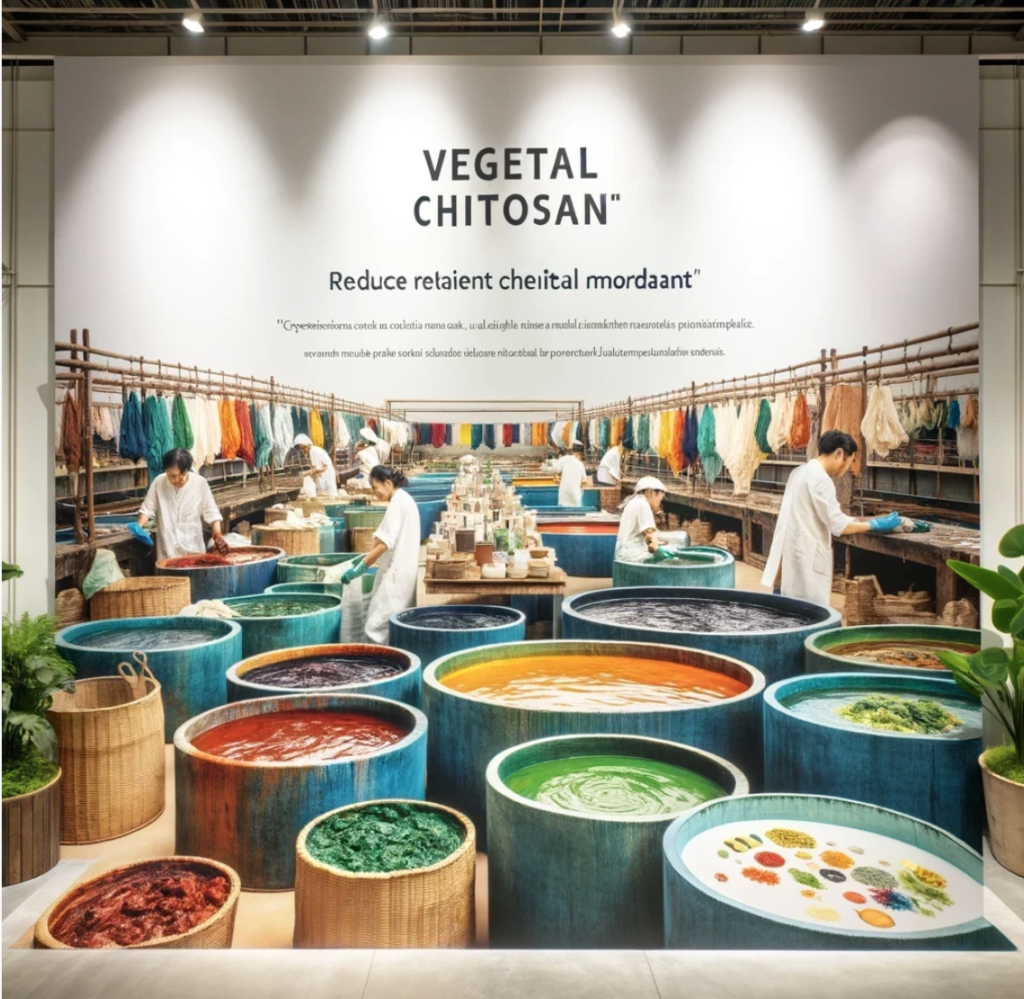

3. What are the benefits, functions of vegetal chitosan in textile uses?

Vegetal chitosan, derived from sources such as mushrooms & aspergillus niger, offers several benefits and functions when applied in textiles:

Benefits of Vegetal Chitosan in Textiles:

- Biodegradability: Vegetal chitosan, being a natural biopolymer, offers an ecologically sound alternative to synthetic agents. Its biodegradable nature contributes to reducing environmental impact, aligning with sustainable textile manufacturing practices.

- Eco-Friendly Dyeing Process: Utilized as a natural mordant in the dyeing process, chitosan assists in minimizing the reliance on harsh chemical mordants, thereby reducing environmental pollutants and enhancing the sustainability of the dyeing process.

- Green Footprint: The use of vegetal chitosan contributes to the overall ecological footprint reduction of textile production, supporting industry shifts toward greener and more responsible manufacturing methods.

- Non-Toxicity: Unlike many chemical additives, vegetal chitosan is non-toxic, making it safe for use in a wide range of textile applications, including those that come into close contact with skin.

- Biocompatibility: Its inherent biocompatibility makes it particularly valuable in medical textiles, where it poses minimal risk of skin irritation or allergic reactions, a crucial factor in healthcare-related fabric applications.

Functions of Vegetal Chitosan in Textiles:

- Antimicrobial Properties: Chitosan’s antimicrobial properties are pivotal in inhibiting microbial growth, making it ideal for hygiene-critical applications such as medical textiles, sportswear, and inner-wear. This function is vital for maintaining sanitary conditions and preventing odor buildup in fabrics.

- Moisture Absorption and Breathability: Its ability to absorb moisture enhances fabric breathability and comfort, especially in apparel textiles where moisture control is essential for wearer comfort.

- Strength and Durability: The incorporation of chitosan can bolster the mechanical strength and durability of textiles, thus extending the lifespan and wearability of the fabric.

- UV Protection: Chitosan-treated textiles offer a shield against harmful ultraviolet rays, adding a layer of protection that is especially beneficial in outdoor and sun-exposed garments.

- Wound Healing (in Medical Textiles): Leveraging its wound healing capabilities, chitosan is invaluable in medical textiles, promoting healing processes in wound dressings and other medical fabrics.

- Odor Resistance: Reduces odors in textiles, making them more pleasant to wear.

- Water Treatment: Beyond traditional textiles, chitosan-coated fabrics can be utilized in innovative water treatment applications, exploiting its ability to bind with heavy metals and pollutants, offering a novel approach to water purification.

- Flame Retardancy: Incorporating chitosan imparts flame-retardant properties to textiles, an essential function for safety in various applications, including upholstery, draperies, and protective clothing.

- Static Resistance: In synthetic fabrics, chitosan can help reduce static build-up, enhancing comfort and usability in diverse textile products.

In conclusion, vegetal chitosan plays a multifaceted role in the textile industry. Its benefits extend from enhancing environmental sustainability and safety to improving the functional properties of fabrics. Its versatility and eco-friendly profile make it an increasingly popular choice in the ongoing evolution of textile technology and sustainable practices.

4. What are the common forms of chitosan used in textile uses?

In the textile industry, vegetal chitosan is utilized in several common forms, each catering to specific functionalities and applications, with provided specific dosage suggestions for each form of vegetal chitosan in textile applications:

- Fiber Form:

- Chitosan fibers are directly woven or blended with other natural or synthetic fibers to create composite fabrics. This integration imparts chitosan’s unique properties, such as antimicrobial and moisture-wicking abilities, directly into the fabric structure.

- When chitosan is integrated into fibers, the concentration can vary significantly. A common ratio might be anywhere from 5% to 30% of chitosan blended with other fibers. The exact ratio depends on the desired properties and the compatibility with other fibers.

- Powder Form:

- As a fine powder, chitosan can be applied to textiles through various finishing processes. The powder form is particularly useful for treatments that require a more surface-level application, enabling easy integration with other textile finishing chemicals.

- For powder application, the dosage can vary from 1% to 5% by weight of the fabric, depending on the desired effect. Higher concentrations generally provide more pronounced antimicrobial and durability effects.

- Solution or Liquid Form:

- Chitosan is often dissolved in a liquid medium (usually in acetic acid or other solvents) to create a solution. This chitosan solution can be applied to textiles through techniques like padding, spraying, or coating. This method is especially effective for treatments aiming to provide a thin, even coating over the fabric, useful for antimicrobial finishes or UV protection.

- In solution form, chitosan is often used in concentrations ranging from 0.5% to 2% (w/v). The exact concentration depends on the method of application (e.g., padding, spraying) and the desired finish.

- Gel Form:

- In some applications, chitosan is used in a gel-like form, which is suitable for coating or impregnating textiles. This form is particularly beneficial for medical textiles, where a more substantial layer of chitosan can aid in wound healing and antibacterial properties.

- Gel applications, particularly in medical textiles, can vary widely in concentration. Typically, a gel containing 1% to 3% chitosan might be used, but this can be adjusted based on the required thickness and therapeutic effect.

- Nano-form or Micro-encapsulation:

- Chitosan nanoparticles or microcapsules are used for more targeted and controlled release of the chitosan’s properties. These nano-scale or micro-encapsulated forms can be integrated into fabrics to provide specific functionalities like gradual release of antimicrobial agents or targeted application in smart textiles.

- The dosage of nano-sized or micro-encapsulated chitosan is typically quite low, as the encapsulation increases the efficiency of the active substance. Concentrations as low as 0.1% to 1% can be effective.

- Composite Form:

- Chitosan is also used in composite materials, where it is combined with other polymers or additives to enhance or modify its properties. These composites can be tailored for specific functional requirements like increased durability, enhanced moisture management, or improved biodegradability.

- In composite materials, chitosan is usually combined with other polymers or additives at ratios that depend heavily on the desired end properties. For instance, a 5% to 20% chitosan composite might be used to enhance antimicrobial properties or fabric strength.

- Film Form:

- Chitosan films, created by drying chitosan solutions, can be applied to textiles. These films are particularly useful in packaging and protective clothing, where they provide a barrier against microorganisms and external elements.

- Chitosan films are generally created from solutions with a higher concentration, possibly around 2% to 4%, to ensure the film’s integrity and effectiveness. The exact concentration depends on the desired film thickness and application.

Each form of vegetal chitosan offers different advantages and is chosen based on the desired outcome, the nature of the textile material, and the specific requirements of the end product. The versatility of these forms allows for widespread use in various textile applications, from everyday wear to high-tech and medical textiles.

It’s important to note that these are approximate guidelines. The optimal dosage and concentration of chitosan in each form should be determined through experimentation and testing, considering the specific requirements of the textile product and its intended use. Additionally, the processing conditions, such as temperature and time, play a significant role in the effectiveness of chitosan in each form.

5. Considering solubility and viscosity, which type of chitosan is optimal for textile applications?

The choice of the best type of chitosan for textiles depends on the specific application and desired properties of the finished product. Each type of chitosan mentioned has unique characteristics that make it suitable for different textile applications:

- Acid-Soluble Chitosan:

- Best for applications where a soluble form is needed, like coatings or treatments in liquid form.

- Useful for creating films or sheaths on fibers.

- Chitosan Hydrochloride (Water-soluble):

- Soluble in water, making it convenient for applications where water solubility is a priority.

- Often used in dyeing processes and for antimicrobial finishes.

- Chitosan Oligosaccharide (Water-soluble):

- Has a lower molecular weight, leading to better solubility and penetration into fibers.

- Ideal for applications requiring deeper penetration into the fabric, like deep conditioning or functional treatments.

- Carboxymethyl Chitosan (Water-soluble):

- Highly water-soluble and has enhanced biocompatibility.

- Often used in medical textiles and skin-friendly applications.

Regarding viscosity, it largely depends on the method of application and the desired effect:

- Lower Viscosity (20-200 cps):

- Better for processes like spraying or dipping, where a thinner, more penetrative solution is needed.

- Suitable for light coatings and treatments that require minimal alteration of the fabric’s hand feel and drape.

- Higher Viscosity (200-1000 cps):

- Better for heavier coatings, where a thicker layer is required.

- Ideal for applications where a substantial layer of chitosan is beneficial, such as in certain types of medical textiles or protective coatings.

The choice of chitosan type and viscosity should align with the specific requirements of the textile application, including factors like the fabric type, desired properties (e.g., antimicrobial, UV protection, moisture management), and the application process. Often, trial and testing are necessary to determine the most suitable type and viscosity of chitosan for a given textile product.

6. What distinguishes crustacean chitosan from vegetal chitosan (sourced from mushrooms and Aspergillus Niger) in textile applications?

Crustacean chitosan and vegetal chitosan, while similar in their basic chemical structure, have some key differences, particularly in their source, properties, and implications for use in textiles:

1). Source

- Crustacean Chitosan: Derived primarily from the shells of crustaceans like shrimp, crabs, and lobsters. These shells are a byproduct of the seafood industry and are the most common source of chitosan.

- Vegetal Chitosan: Sourced from fungi, such as mushrooms or Aspergillus Niger. This form of chitosan is an alternative for those seeking non-animal-based sources.

2). Allergenic Potential

- Crustacean Chitosan: May pose allergenic risks for individuals allergic to shellfish. Its use in textiles that come into direct contact with skin could be a concern for this demographic.

- Vegetal Chitosan: Generally considered hypoallergenic and is a safer choice for people with shellfish allergies. This attribute makes it particularly suitable for textiles used in clothing and medical applications.

3). Environmental and Ethical Considerations

- Crustacean Chitosan: While it uses a byproduct of the seafood industry, there are environmental and ethical considerations regarding the sourcing from sea creatures.

- Vegetal Chitosan: Often viewed as more sustainable and ethical, particularly appealing to vegan and environmentally conscious consumers and manufacturers.

4). Molecular Structure and Properties

- Crustacean Chitosan: Typically has a higher degree of deacetylation, which can influence its solubility and effectiveness in certain applications.

- Vegetal Chitosan: The molecular structure may differ slightly due to its fungal origin. These differences can affect its solubility, biocompatibility, and interaction with textile fibers.

5). Application in Textiles

- Crustacean Chitosan: Commonly used for its antimicrobial properties, strength enhancement, and moisture management in textiles.

- Vegetal Chitosan: Also valued for similar properties but is especially preferred in applications where hypoallergenic or vegan materials are important.

6). Regulatory and Market Aspects

- Crustacean Chitosan: More widely used and researched, with established supply chains.

- Vegetal Chitosan: Emerging as a popular alternative, with increasing research and market presence, especially in sectors prioritizing sustainable and ethical materials.

In summary, while both types of chitosan offer beneficial properties for textile applications, the choice between crustacean and vegetal chitosan often comes down to considerations of allergies, sustainability, ethical sourcing, and specific molecular properties required for the textile application.

7. Which source of chitosan (crustacean or vegetal) is more suitable for each form used in textiles?

The choice of source for chitosan – whether crustacean or vegetal – for different forms used in textiles depends on various factors, including the desired properties, application methods, and sustainability considerations. Here’s a general guideline for which source might be better for each form:

1). Fiber Form

- Crustacean Chitosan: Offers strong antimicrobial properties and durability, useful for durable and hygienic textiles.

- Vegetal Chitosan: Preferred for hypoallergenic applications and for consumers seeking vegan materials.

2). Powder Form

- Crustacean Chitosan: Effective for general antimicrobial and strength-enhancing applications.

- Vegetal Chitosan: Better suited for environmentally conscious brands and for textiles marketed as vegan or organic.

3). Solution or Liquid Form

- Crustacean Chitosan: Commonly used for its strong antimicrobial properties in coatings.

- Vegetal Chitosan: Ideal for applications where a non-animal-derived product is crucial, such as in eco-friendly or hypoallergenic textiles.

4). Gel Form

- Crustacean Chitosan: Effective for wound-healing medical textiles due to its strong bioactive properties.

- Vegetal Chitosan: Preferred in medical textiles where hypoallergenic properties are important, or for vegan products.

5). Nano-form or Micro-encapsulation

- Crustacean Chitosan: Offers effective controlled release properties due to its molecular structure.

- Vegetal Chitosan: Suitable for applications requiring environmentally friendly and non-animal-derived materials.

6). Composite Form

- Crustacean Chitosan: Good for enhancing strength and antimicrobial properties in composites.

- Vegetal Chitosan: Used in composites for eco-friendly or vegan textiles, or when hypoallergenic properties are required.

7). Film Form

- Crustacean Chitosan: Creates effective films for protective textiles due to its strong barrier properties.

- Vegetal Chitosan: Ideal for sustainable, eco-friendly packaging solutions or textiles.

Conclusion

In choosing between crustacean and vegetal chitosan, consider factors like the target market, environmental and ethical concerns, the specific properties required in the textile application, and potential allergy considerations. Both sources offer unique benefits, and the best choice varies depending on the specific requirements and values of the end product.

8. Summarizing vegetal chitosan applications in textiles

In the evolving landscape of textile innovation, vegetal chitosan emerges as a frontrunner, offering a harmonious blend of environmental sustainability and functional superiority. Sourced ethically from non-animal origins like mushrooms and Aspergillus Niger, this biopolymer is capturing the attention of the industry, particularly for clients seeking eco-friendly and hypoallergenic alternatives.

Vegetal chitosan stands out for its remarkable versatility, being adaptable in various forms such as fibers, powders, and solutions, each catering to specific textile needs. Its integration into fabrics enhances properties like antimicrobial effectiveness, moisture management, and UV protection, all while maintaining a gentle footprint on the environment.

As the textile sector gravitates towards sustainable and ethically sourced materials, vegetal chitosan sets a benchmark for future innovations. Whether it’s in medical textiles requiring hypoallergenic properties, performance wear demanding moisture-wicking capabilities, or eco-conscious fashion seeking sustainable materials, vegetal chitosan offers a tailored solution. Its potential extends beyond traditional textiles, finding novel applications in water treatment and smart fabric technologies.

For players in the textile industry, embracing vegetal chitosan not only means investing in quality and functionality but also contributing to a greener, more sustainable future.