Oyster Mushroom Carboxymethyl Chitosan

Oyster Mushroom Carboxymethyl Chitosan

Additional information

| Product Name | Oyster Mushroom Carboxymethyl Chitosan |

|---|---|

| Form | Off-white to white powder |

| Source | Oyster mushroom (Scientific name: Pleurotus ostreatus) |

| Cas No. | 83512-85-0 |

| Specification | N,O-CMC, Substitution degree: NLT 90% |

| Main Applictions | Pharmaceuticals, Wound Healing, Cosmetics, Tissue Regeneration etc. |

Product Details

What is Oyster Mushroom Carboxymethyl Chitosan?

What is Oyster Mushroom Carboxymethyl Chitosan?Oyster Mushroom Carboxymethyl Chitosan is a water-soluble derivative of chitosan derived from Pleurotus ostreatus (oyster mushrooms).

Dual N,O- Substituted Oyster Mushroom Carboxymethyl Chitosan (N,O-CMC) – Premium Quality from Chibio Biotech

What is Dual N,O-Substituted Oyster Mushroom Carboxymethyl Chitosan (N,O-CMC)?

Dual N,O-Substituted Oyster Mushroom Carboxymethyl Chitosan (N,O-CMC) is an advanced, water-soluble derivative of chitosan, where both the amino and hydroxyl groups of the chitosan molecule are modified with carboxymethyl groups.

Derived from Pleurotus ostreatus (oyster mushrooms), this unique modification significantly enhances its solubility, functionality, and versatility, making it ideal for applications in pharmaceuticals, cosmetics, agriculture, and more.

CAS Number:

- CAS No.: 83512-85-0

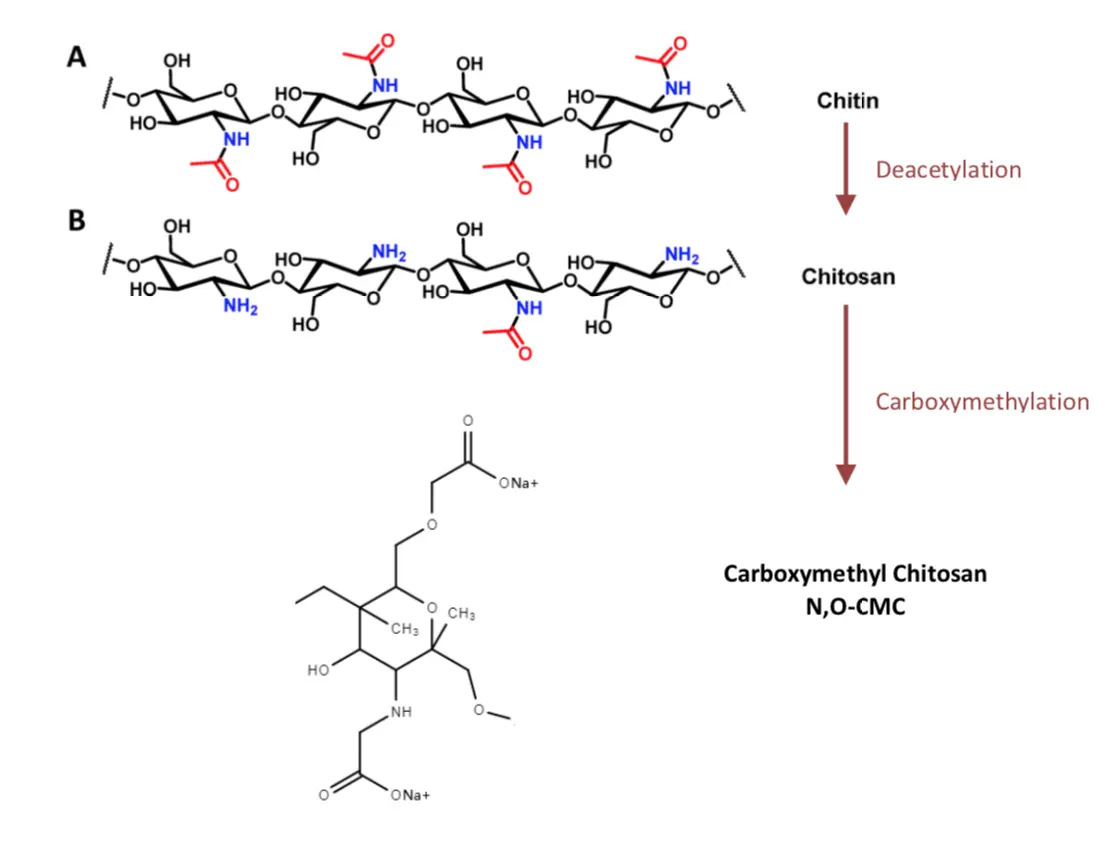

Chemical Structure:

- Chemical Formula: (C8H15NO7)n(C_8H_{15}NO_7)_n(C8H15NO7)n

- The chemical structure of dual substituted carboxymethyl chitosan includes both amino (–NH_2) and hydroxyl (–OH) groups that are substituted with carboxymethyl groups (–CH_2COOH). This dual substitution increases the polymer’s solubility and enhances its functional properties, such as biocompatibility and bioactivity.

The repeating unit can be represented as:

- [–(C_6H_{9}O_4)–NH–CH_2–COOH–]n + [–C_6H_{9}O_4–O–CH_2–COOH–]n

Where:

- NH represents the amino group substitution, and O represents the hydroxyl group substitution with carboxymethyl groups.

- “n” represents the degree of polymerization, which can vary based on specific applications.

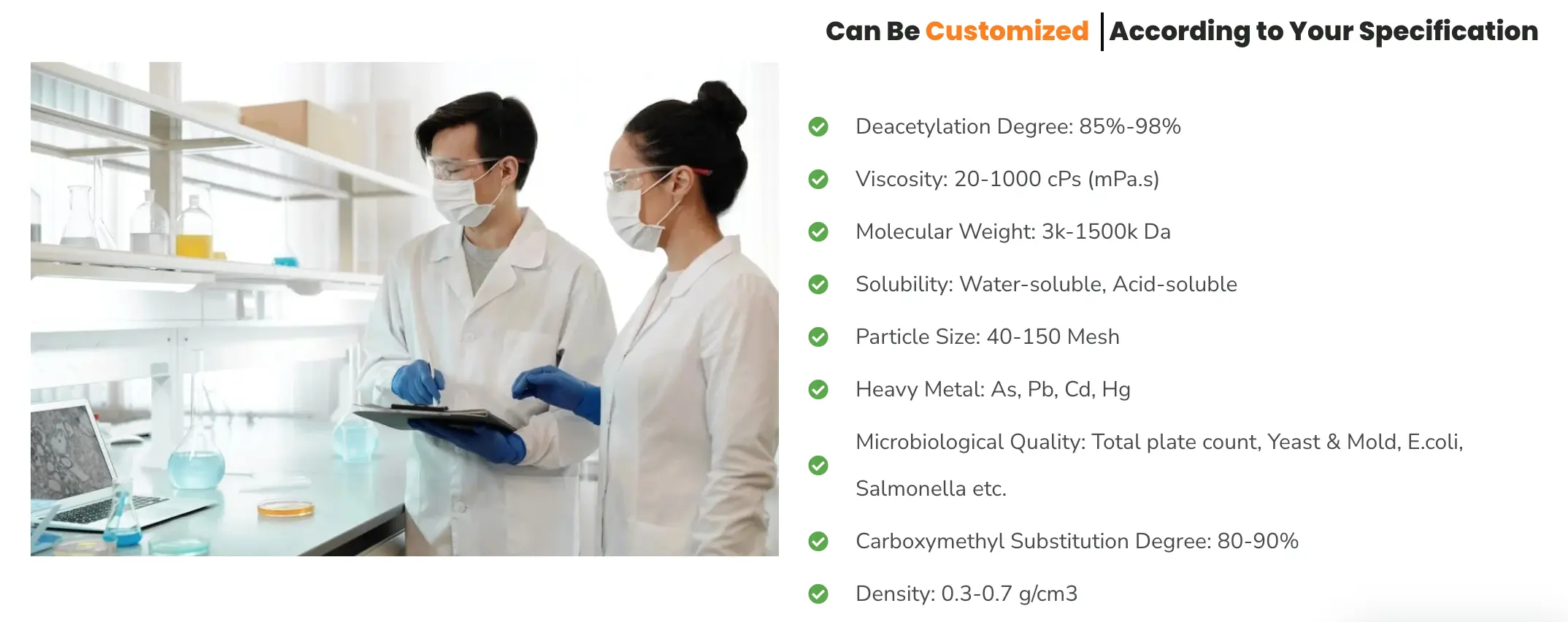

Specification

- Appearance: Off-white to light yellow powder

- Degree of Substitution (DS): Typically not less than 90%

- Viscosity: 10-80cps (typically around 60cps, maximum 100-200cps)

- Molecular Weight: Varies depending on application requirements

- Solubility: Highly soluble in water

This table illustrates a direct correlation between the viscosity and molecular weight of chitosan, where higher molecular weights result in increased viscosity. This relationship is crucial for selecting the appropriate chitosan grade for various applications, as higher viscosity chitosan, due to its larger molecular structure, is ideal for creating thicker gels and films.

Solubility

This dual substituted chitosan is fully soluble in water, with ration 1% (1g chitosan dissolved in 99ml water), offering excellent stability and functionality across a wide pH range, making it suitable for diverse applications.

Kindly watch the videos of solubility of different types of vegetal chitosan: https://www.chibiotech.com/video/

Specification Customized Service

We provide tailored solutions to modify the degree of substitution, molecular weight, and other properties to meet the specific needs of your application, ensuring optimal performance and efficiency.

Advantages & Benefits

- Enhanced Water Solubility: Dual substitution ensures complete solubility in water, allowing for versatile use in various formulations.

- Vegan and Non-Allergenic: Sourced from mushrooms, it is suitable for vegans and those with shellfish allergies.

- High Biocompatibility: Safe for use in medical, pharmaceutical, and cosmetic applications, with minimal risk of adverse reactions.

- Eco-Friendly: Produced using sustainable practices, contributing to environmental preservation.

Functions

- Superior Moisturizing Agent: Excellent for retaining moisture, making it ideal for skincare and cosmetic products.

- Biodegradability: Environmentally friendly, it naturally decomposes without harming ecosystems.

- Film Formation: Capable of forming strong, flexible, and water-soluble films for packaging and coating applications.

- Antimicrobial Properties: Effectively inhibits the growth of bacteria and fungi, ensuring product safety and longevity.

Main Applications (More about applications)

- Pharmaceuticals: Utilized in drug delivery systems and as a stabilizing agent in various formulations.

- Cosmetics: Enhances skin moisturization, protection, and texture in lotions, creams, and gels.

- Wound Healing: Promotes faster and more effective healing of wounds due to its biocompatibility and antimicrobial properties.

- Tissue Regeneration: Supports tissue regeneration and repair, making it valuable in biomedical applications.

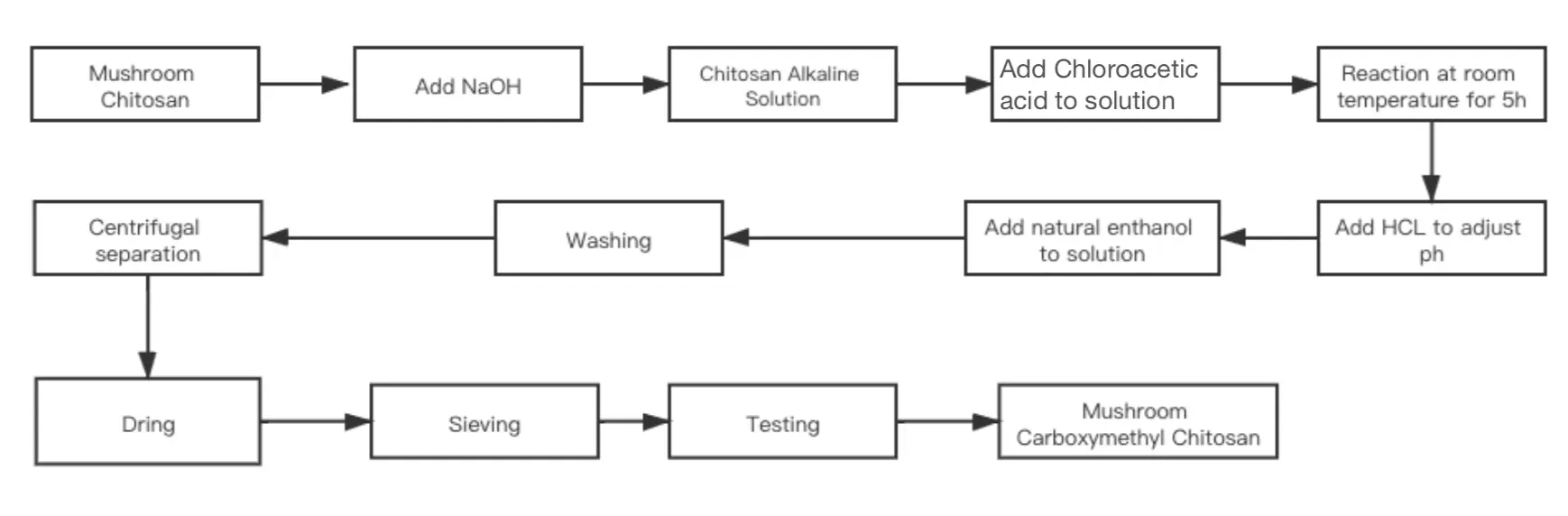

Flowchart

The production process of oyster mushroom carboxymethyl chitosan involves the careful modification of both amino and hydroxyl groups, followed by washing, drying, sieving, and rigorous testing to ensure the highest quality.

Our production process adheres to strict quality standards, ensuring the highest purity and efficacy from raw material sourcing to final product packaging.  The flowchart of oyster mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

The flowchart of oyster mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

- Starting Material: The process begins with mushroom material as the source.

- Filtration: The mushroom material undergoes a filtration process.

- Protein Removal: Proteins are then removed from the filtered material using an alkali solution.

- Ash Removal: Ash content is subsequently removed with acid.

- Chitin Extraction:

- Acid is added without bubbles to proceed to the next stage.

- Chitin is extracted, which is not soluble in acid.

- An acetylation step removes the acetyl groups from the chitin using sodium hydroxide (NaOH), converting it into chitosan, which is soluble in acid.

- Drying: The acid-soluble chitosan is then dried to produce the final mushroom chitosan product, showcased as a white powder.

- Chitosan Derivatives: Parallel to the drying process, there is a branch leading to the production of various chitosan derivatives:

- Chitosan Hydrochloride: Chitosan converted into its hydrochloride form.

- Enzyme Hydrolysis: Produces chitosan oligosaccharide through enzymatic hydrolysis.

- Carboxymethyl Chitosan: Derived through the carboxymethylation of chitosan.

The flowchart depicts a methodical approach to converting mushroom material into various forms of chitosan, focusing on the purification and chemical modification steps necessary to achieve different chitosan-based products for use in various applications.

Here is a simplified description of the flowchart for Oyster Mushroom Carboxymethyl Chitosan production:

- Start with Mushroom Chitosan: The process begins with the preparation of mushroom-derived chitosan.

- Alkaline Solution Preparation: Add NaOH to create an alkaline solution.

- Carboxymethylation: Add chloroacetic acid to introduce carboxymethyl groups into the chitosan.

- pH Adjustment: Adjust the pH by adding HCl.

- Ethanol Addition: Add natural ethanol to the solution.

- Washing and Centrifugation: The product undergoes washing, followed by centrifugal separation.

- Drying and Sieving: The product is then dried and sieved.

- Final Testing: The final product, Mushroom Carboxymethyl Chitosan, is tested for quality assurance.

Why Choose Us? (>>See more about us)

- Expertise: With over 8 years of experience, Chibio Biotech is a leading provider of high-quality vegetal chitosan, trusted by clients worldwide.

- Certified Quality: Our products are ISO 22000:2018, Halal, Kosher, and Organic certified, ensuring adherence to the highest industry standards. (>>See more about our certificates)

- Customized Solutions: We offer bespoke chitosan solutions tailored to your specific needs, ensuring the best performance for your applications.

- Global Reach: Serving customers in over 50 countries, we have the expertise and capacity to support your business wherever you are.

Why your businesses consider using vegetal chitosan?

Using vegetal chitosan in your applications or formulations offers significant benefits to businesses, as outlined below:

- Eco-Friendly and Sustainable: Vegetal chitosan is derived from plant sources such as mushrooms and fungi, making it an environmentally sustainable alternative to traditional animal-based chitosan. This aligns with growing consumer demand for green and eco-friendly products.

- Non-Allergenic and Vegan-Friendly: Unlike crustacean-derived chitosan, vegetal chitosan does not trigger shellfish allergies and is suitable for vegan and vegetarian consumers. This widens the market reach for products formulated with vegetal chitosan.

- Versatility and Superior Functionality: Vegetal chitosan offers excellent biocompatibility, biodegradability, and antimicrobial properties. These attributes enhance its utility across various industries, including food, pharmaceuticals, cosmetics, textiles, and agriculture.

- Enhanced Product Performance: In many applications, vegetal chitosan improves product qualities such as moisture retention, antimicrobial efficacy, and barrier properties. This leads to better-performing end products, such as longer shelf-life for food items or improved durability and functionality in textiles.

- Market Differentiation: Incorporating vegetal chitosan allows companies to differentiate their products by promoting natural, sustainable, and allergen-free claims, which are increasingly valued by health-conscious and environmentally aware consumers.

In summary, using vegetal chitosan can help your businesses enhance their product offerings, meet consumer demands for sustainable and non-allergenic ingredients, and improve your overall market positioning.

Discover the benefits of Oyster Mushroom Carboxymethyl Chitosan today! Contact us for more details or to request a custom quote.

Get in touch with us to boost your business

- Get Free Sample

- Get Step Quote

- 24/7 Service

- Customized Specification

- Confidentiality Agreement

Headquarter

Block B, Vanke Center, No.2 Heilongjiang South Road, Shibei District, Qingdao City, China 266033

Phone

+86 (0)532 66983270

Cellphone / WhatsApp / WeChat

+86 156 6577 2296

+86 133 8100 5417