Natamycin

Natamycin

Additional information

| Product Name | Natamycin (e235) |

|---|---|

| Source | Produced via controlled fermentation of Streptomyces natalensis |

| Appearance | White to off-white powder |

| Assay | ≥95% (Pure) / ≥50% (Blended) in lactose & glucose |

| Cas No# | 7681-93-8 |

| Chemical Formula | C33H47NO13 |

| Solubility | Slightly soluble in water, effective at low concentrations |

| Main Functions | Effectively inhibits molds, yeasts, and fungi without affecting bacteria. |

| Main Applications | Dairy Industry, Meat & Poultry, Bakery, Beverage & Drinks |

Product Details

Natamycin – A Natural Antifungal Preservative for Food & Beverages

Protect your products from spoilage & extend shelf life with high-quality Natamycin from Chibio Biotech!

What is Natamycin?

Natamycin is a natural antifungal compound used to inhibit the growth of molds, yeasts, and fungi in food and beverages. Unlike synthetic preservatives, Natamycin is naturally derived from fermentation using Streptomyces natalensis, making it a clean-label and safe solution for food preservation.

Natamycin is FDA-approved, EFSA-certified, and classified as GRAS (Generally Recognized as Safe). It is widely used in the dairy, meat, bakery, and beverage industries to prevent spoilage and extend shelf life.

As a food additive, it has E number E235. Throughout the European Union, it is only approved as a surface preservative for certain cheese and dried sausage products.

Natamycin is also called pimarcin or tennecetin, which is produced by Streptomyces sp. and purified by modern separation technology.

Natamycin is a fungicide that prevents yeasts and moulds from appearing in foods. It is extremely effective when used in small amounts. It is used in smaller quantities than potassium sorbate, and unlike other sorbates it prevents yeasts and moulds from migrating into the product, eliminating the cost of reapplication.

The action of natamycin does not destroy other microorganisms, meaning that it does not alter the food’s natural maturing process. Natamycin contains 50% lactose/glucose/salt and 50% Natamycin, which prevents the formation of moulds and yeasts on the surface.Unlike other antimicrobial agents, it does not affect the appearance, taste or colour of the products.

Natamycin Product Details

Source of Natamycin

Natamycin is produced via controlled fermentation of Streptomyces natalensis, a naturally occurring soil bacterium. It is then extracted, purified, and processed into different formulations to suit various industry needs.

Chemical Information

- CAS Number: 7681-93-8

- Chemical Formula: C33H47NO13

- Molecular Weight: 665.73 Da

- Appearance: White to off-white powder

- Solubility: Slightly soluble in water, effective at low concentrations

-

The solubility of Natamycin is very low in water and in most organic solvents. Only 50mg Natamycin can be dissolved in pure water at room temperature. The low solubility makes it very suitable for use on the surface of food. Natamycin will stay on surface of food, where most moulds and yeasts may grow, but does not influence the natural course of fermentation inside.

-

Natamycin Specifications

| Parameter | Specification |

|---|---|

| Assay (Natamycin content) | ≥95% (Pure) / ≥50% (Blended) |

| Solubility | Slightly soluble in water |

| pH Stability | Stable at pH 5.0 – 7.5 |

| Loss on drying | ≤8.0% |

| Lead (Pb) | ≤5.0 ppm |

| Arsenic (As) | ≤3.0 ppm |

Key Advantages & Benefits of Natamycin

✅ Broad-Spectrum Antifungal Activity – Effectively inhibits molds, yeasts, and fungi without affecting bacteria.

✅ Enhances Food Safety – Protects against spoilage, ensuring longer shelf life.

✅ Minimal Impact on Taste & Texture – Does not alter the sensory properties of food.

✅ Heat & pH Stability – Maintains efficacy in a wide range of food processing conditions.

✅ Clean-Label & Natural – A fermentation-derived alternative to synthetic preservatives.

✅ Regulatory Approved – Recognized as safe by FDA, EFSA, WHO, and other global authorities.

Functions of Natamycin

- Prevents mold and yeast growth in dairy, meat, and baked goods.

- Prolongs shelf life of food products without chemical additives.

- Protects against fungal contamination in food production and packaging.

- Reduces the need for refrigeration, lowering storage and distribution costs.

Microbiological effectiveness:

Various laboratories and testing methods have proved the effectiveness of Natamycin against moulds, yeasts and other fungal growths. Natamycin does not act against bacteria, viruses or other organisms such as protozoa. The quantity and the method of application of Natamycin vary according to the type of foodstuff to be protected and the initial microbial level.

Applications of Natamycin

Natamycin is both safe and effective at protecting WINE, FRUIT JUICES, CHEESES and OTHER FOOD PRODUCTS from the deterioration caused by moulds, yeasts and other fungal growths.

USED IN: Outer surfaces of cheeses, Sausages and meat products, Dairy products, Fruit juices and concentrates,Wines.

1. Dairy Industry

- Cheese Preservation – Surface treatment to prevent mold and yeast growth.

- Yogurt & Fermented Milk – Keeps products fresh without affecting beneficial bacteria.

- Milk-Based Desserts – Ensures prolonged shelf stability.

2. Meat & Poultry

- Processed Meat – Protects against fungal contamination without interfering with flavor.

- Cured & Smoked Meats – Prevents spoilage and extends storage life.

3. Bakery & Confectionery

- Bread & Cakes – Prevents mold growth while maintaining texture.

- Pastries & Snacks – Enhances freshness without artificial preservatives.

4. Beverages & Fermented Drinks

- Fruit Juices & Soft Drinks – Stops yeast growth in natural beverages.

- Wine & Beer – Prevents unwanted fermentation by yeast contamination.

Usage Level:

Natamycin has a low level of solubility – 50g per liter of water at ambient temperature. To obtain the definitive dosage, the preparation of a concentrated suspension in water is recommended.

The recommended dosage of Natamycin is 10g about per 1,000 liters. Natamycin can be applied to the surface of cheeses and sausages through the immersion of the product in an aqueous solution of Natamycin or by spraying the whole of the outside of the product with the aqueous solution.

The most common concentration of Natamycin varies from 1,000 to 2,000 ppm of Natamycin, though some applications require greater or lesser concentrations.

| Applications | Suggested Dosage (Based on Natamycin 95%) |

Method |

| Processed Cheese | 20 mg/kg | Add prior to mixing |

| Tomato purée /paste | 15 mg/kg | Add during mixing |

| Hard/semi-hard cheese | 2.5-4 g./litre | Coat or dip in a solution made with for example distilled water |

| Meat products | 2.5-4 g./litre | Spray or dip in a solution made with for example distilled water |

| Bakery products | 2.5-4 g./litre | Spray with a solution made with for example distilled water |

| Yogurt | 10-20 mg/kg | Add to yogurt mix |

| Fruit and vegetable juice(pulp) | 5-10 mg/kg | Add during mixing |

| Salad dressing | 10-20 mg/kg | Add during mixing |

| Fermenting wine | 5-10 mg/litre | Add to wine mix |

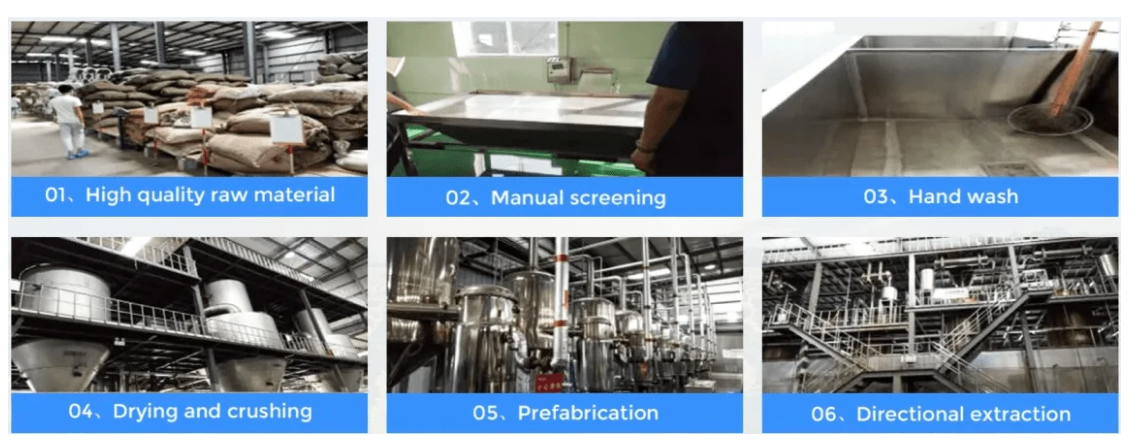

Production Process of Natamycin

1️⃣ Fermentation – Cultivation of Streptomyces natalensis under controlled conditions.

2️⃣ Extraction – Isolation and purification of Natamycin.

3️⃣ Filtration & Concentration – Removal of unwanted components.

4️⃣ Drying & Powder Formation – Processed into powder form for commercial use.

5️⃣ Quality Testing – Ensuring regulatory compliance and purity.

6️⃣ Packaging & Distribution – Available in various formulations for different applications.

Comparison of Natamycin 95%, Natamycin 50% in Lactose, and Natamycin 50% in Glucose

| Feature | Natamycin 95% (Pure) | Natamycin 50% in Lactose | Natamycin 50% in Glucose |

|---|---|---|---|

| Natamycin Content | ≥95% | ≥50% | ≥50% |

| Carrier | None (pure) | Lactose | Glucose |

| Solubility | Slightly soluble in water | More soluble than pure form | More soluble than pure form |

| Application | Cheese, meat, high-concentration uses | Dairy, cheese coatings, powder blends | Beverage, liquid formulations, food coatings |

| Best Use Case | Highly concentrated, industrial applications | Dairy industry, cheese surface treatment | Liquid food & beverage applications |

| Cost Efficiency | Higher cost per gram | Cost-effective for dairy | Cost-effective for beverages |

Which One Should You Choose?

- Choose Natamycin 95% if you need high-purity, concentrated applications for industrial use.

- Choose Natamycin 50% in Lactose for dairy products, as it blends well with cheese and milk formulations.

- Choose Natamycin 50% in Glucose for liquid foods & beverages, ensuring better solubility and even distribution.

Why Choose Chibio Biotech for Natamycin?

🌱 Premium Quality – High-purity Natamycin with strict quality control.

🌎 Global Certifications – ISO22000, Kosher, Halal, FDA, EFSA, and Organic Certified.

🔬 Strong R&D Expertise – Continuous innovation in natural food preservation.

📦 Reliable Supply Chain – Large-scale production with guaranteed consistency.

💡 Custom Solutions – Tailored formulations based on industry needs.

Why Should Your Business Use Natamycin?

✔ Reduce reliance on artificial preservatives – Meet clean-label consumer demands.

✔ Improve food safety & shelf life – Protect against fungal spoilage.

✔ Comply with global food safety regulations – FDA, EFSA, WHO-approved.

✔ Enhance sustainability – A natural alternative to chemical preservatives.

Get in Touch – Inquiry Now!

Looking for high-quality Natamycin for food, beverage, or pharmaceutical applications?

Contact Chibio Biotech today for bulk orders and technical support!

📩 Email: sales@chibiotech.com

📞 Phone: +86 (0)532 66983270

🌍 Website: www.chibiotech.com

✅ Extend shelf life naturally with Natamycin – The Future of Food Preservation! 🚀

>More details about Comparison between Nisin & e-Polylysine & Natamycin

Get in touch with us to boost your business

- Get Free Sample

- Get Step Quote

- 24/7 Service

- Customized Specification

- Confidentiality Agreement

Headquarter

Block B, Vanke Center, No.2 Heilongjiang South Road, Shibei District, Qingdao City, China 266033

Phone

+86 (0)532 66983270

Cellphone / WhatsApp / WeChat

+86 156 6577 2296

+86 133 8100 5417