1. What is vegetal chitosan?

Chitosan is a natural biopolymer that is primarily derived from chitin, which is the second most abundant natural polysaccharide after cellulose. Chitin is commonly found in the exoskeletons of crustaceans like crabs, shrimps, and lobsters, as well as in the cell walls of certain fungi like mushroom, aspergillus niger.

Structure and Properties:

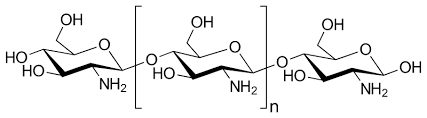

- Chemical Structure: Chitosan is obtained by deacetylating chitin. This process involves removing acetyl groups from chitin, resulting in a polymer that has free amine groups.

- Solubility: Unlike chitin, chitosan is soluble in acidic to neutral solutions, making it more versatile for various applications.

- Biocompatibility and Biodegradability: Chitosan is known for its excellent biocompatibility and biodegradability. It’s non-toxic and can be broken down by natural biological processes.

Chitosan, sometimes known as deacetylated chitin, is a natural polycationic linear polysaccharide derived from partial deacetylation of chitin. Chitin is the structural element in the exoskeleton of insects, crustaceans (mainly shrimps and crabs shell), and cell walls of fungi (oyster mushroom, agaricus bisprous and aspergillus niger), and also is the second most abundant natural polysaccharide after cellulose.

Chitosan, a natural polysaccharide prepared of fungal origin, is initially extracted and purified from reliable and abundant food or biotechnological fungal sources such as Agaricus bisporus or Aspergillus niger.

Chitosan is composed of glucosamine sugar units (deacetylated units) and N-acetyl-D-glucosamine units (acetylated units) interconnected by ß→(1.4) type linkages.

Uses and Applications:

- Medical and Pharmaceutical Fields: Due to its biocompatibility and non-toxic nature, chitosan is used in wound healing, drug delivery systems, and as a biomaterial in tissue engineering.

- Water Treatment: Its ability to bind with heavy metals and other contaminants makes it useful in water purification and treatment processes.

- Agriculture: As a natural biostimulant and elicitor, chitosan is used to enhance plant growth and provide resistance against pathogens.

- Food Industry: It’s used as a food additive for its antimicrobial properties, and as an edible film or coating to enhance the shelf life of perishable food products.

- Cosmetics and Personal Care: In this realm, it finds use as a thickener, moisturizer, and film-forming agent, particularly in hair and skin care products.

Chitosan has been widely used in various fields, including wine, pharmaceuticals, dietary supplement, medicine, agriculture, and food industries, due to its biocompatibility, biodegradability, and non-toxicity. In recent years, researchers have investigated the use of vegetal chitosan, which is derived from fungal or plant sources, as a sustainable alternative for use in wine applications.

Variants:

- Traditional Chitosan: Traditionally sourced from marine crustaceans.

- Vegetal Chitosan: Derived from fungal sources, offering an alternative for those seeking non-animal derived products.

In summary, chitosan’s versatility, biodegradability, and non-toxic nature make it a valuable material across various industries, from healthcare to cosmetics. Its ability to be derived from non-animal sources also makes it an appealing option for vegetarian and vegan-friendly products.

2. What are the advantages of vegetal chitosan?

Vegetal chitosan, also known as fungal chitosan or mycelium chitosan, is a type of chitosan derived from the cell walls of fungi (mushroom and aspergillu niger). It has several advantages over traditional chitosan derived from shellfish, including:

- 1. Vegan and vegetarian-friendly: Vegetal chitosan is an excellent alternative for individuals who avoid animal-based products, such as those who follow a vegan or vegetarian lifestyle.

- 2. Allergen-free: Traditional chitosan is derived from shellfish, which can cause allergic reactions in some people. Vegetal chitosan does not contain any shellfish-derived ingredients, making it an allergen-free option.

- 3. Purer: Vegetal chitosan is often considered to be purer than traditional chitosan because it is derived from a single source, whereas traditional chitosan can be contaminated with other shellfish-related substances.

- 4. Better solubility: Vegetal chitosan is more soluble than traditional chitosan, which makes it easier to incorporate into various applications such as cosmetics, pharmaceuticals, wine and food.

- 5. Improved bioavailability: Some studies have suggested that vegetal chitosan has a higher bioavailability compared to traditional chitosan, which means that it can be absorbed and utilized more effectively by the body.

Overall, vegetal chitosan offers several advantages over traditional chitosan, making it an attractive alternative for individuals and industries looking for a vegan, allergen-free, and more effective chitosan source.

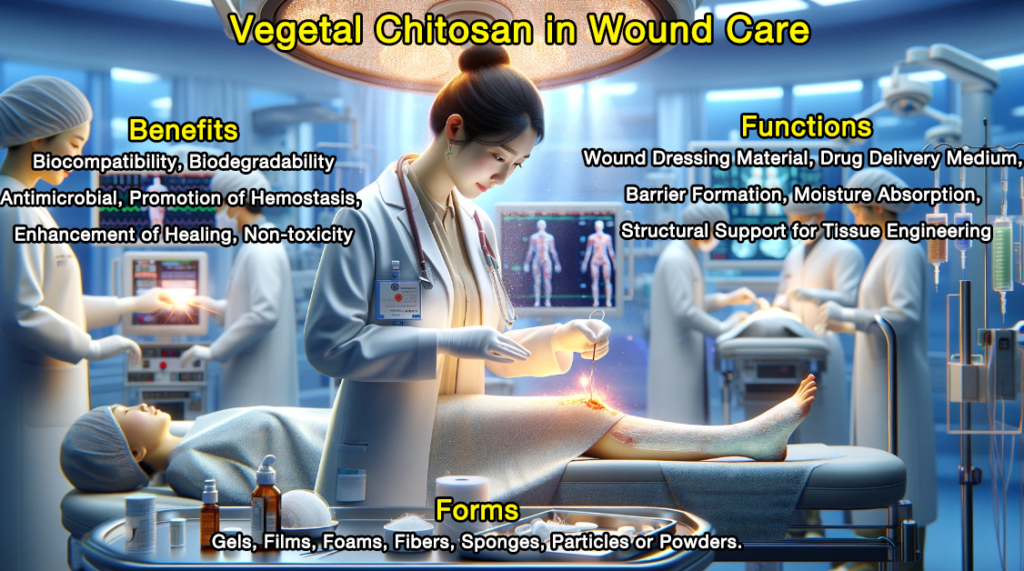

3. What are the benefits & functions of vegetal chitosan in wound care?

Chitosan, derived from sources like oyster mushrooms and Aspergillus niger (from corn fermentation), has several benefits and functions in wound care. Here’s a breakdown:

Benefits of Vegetal Chitosan for Wound Care

- Biocompatibility and Biodegradability: Chitosan is highly biocompatible and biodegradable, making it an excellent material for use in medical applications, particularly in wound care. It can be used in dressings without causing significant immune reactions and naturally breaks down in the body.

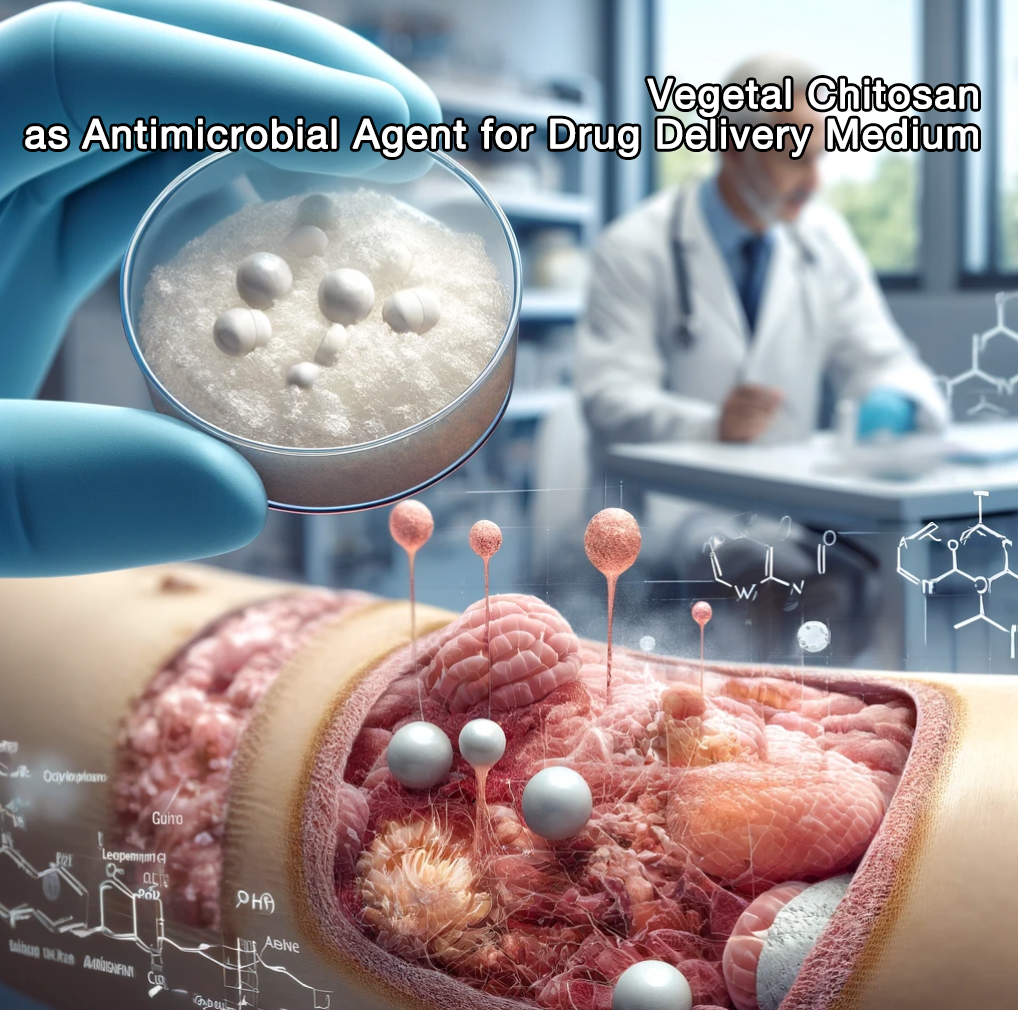

- Antimicrobial Properties: Chitosan has natural antimicrobial properties, which help in preventing wound infections. This is particularly useful in treating open wounds, where the risk of bacterial and fungal infections is high.

- Promotion of Hemostasis: Chitosan is effective in promoting hemostasis (the stopping of bleeding). This makes chitosan-based dressings ideal for managing bleeding in acute wounds, thus reducing overall wound healing time.

- Enhancement of Healing: Chitosan promotes the healing process by enhancing granulation tissue formation and collagen synthesis. This leads to faster and more efficient wound closure.

- Non-toxicity: Being derived from natural sources, chitosan is generally non-toxic, which is crucial for any material used in medical treatments, especially those that are in direct contact with open tissues.

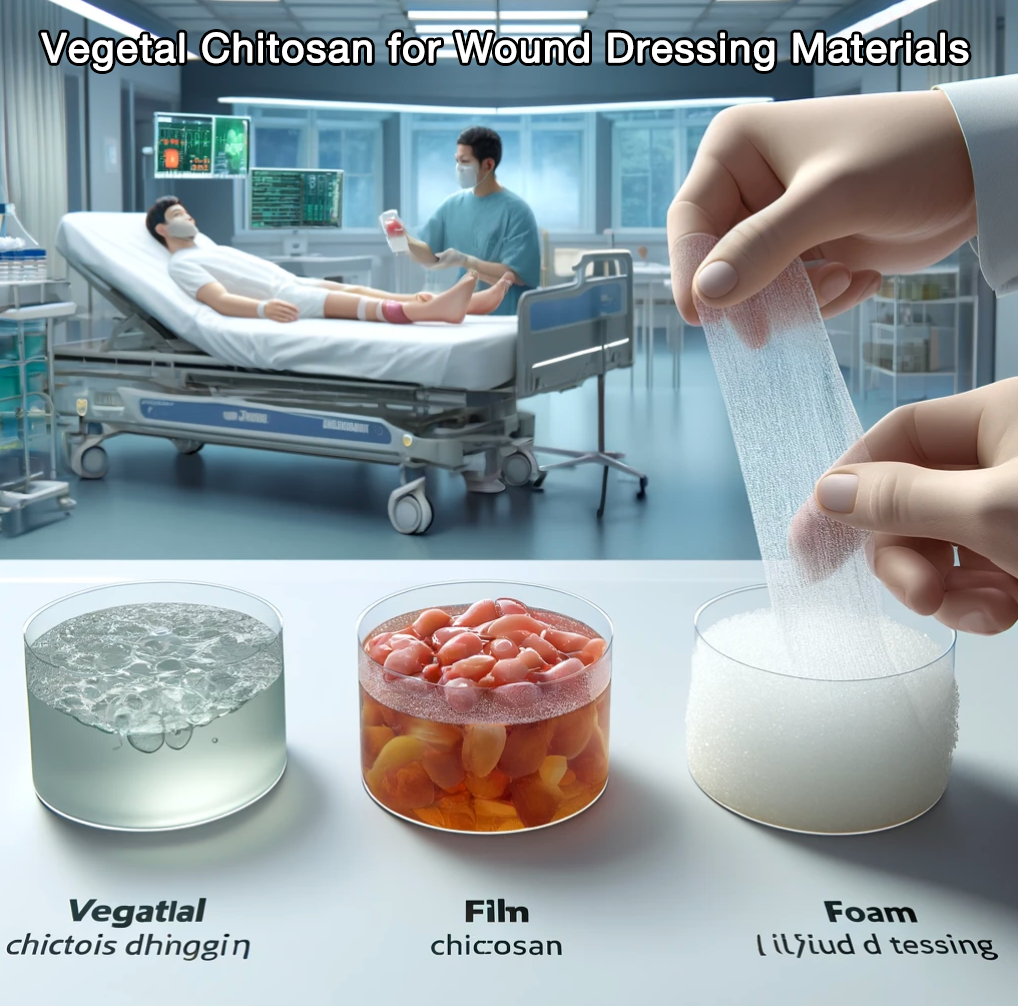

Functions of Vegetal Chitosan in Wound Care

- Wound Dressing Material: Chitosan can be processed into various forms such as gels, films, and foams which are used as dressing materials. These dressings are designed to maintain a moist environment around the wound, which is conducive to healing and helps in pain reduction.

- Drug Delivery Medium: Chitosan’s bioadhesive properties make it an excellent medium for drug delivery. In wound care, chitosan dressings can be impregnated with antimicrobial agents or other medications that promote wound healing, providing targeted therapy directly to the wound site.

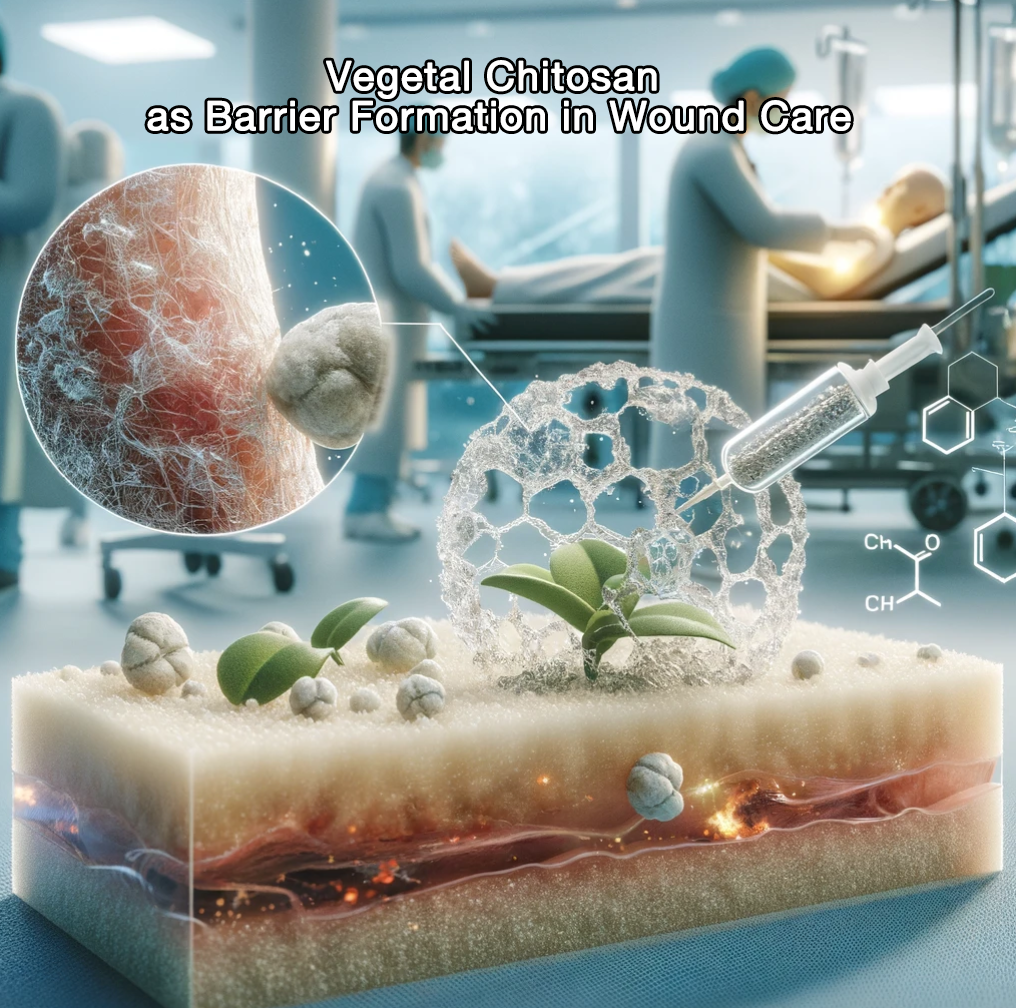

- Barrier Formation: Chitosan forms a semi-permeable barrier on the wound, protecting it from external contaminants while still allowing it to breathe. This barrier supports the natural wound healing environment, reducing the risk of infection and promoting faster healing.

- Moisture Absorption: Chitosan has excellent moisture-absorbing properties. This is important in wound care as it helps in absorbing excess wound exudate, which can otherwise hinder the healing process and promote infection.

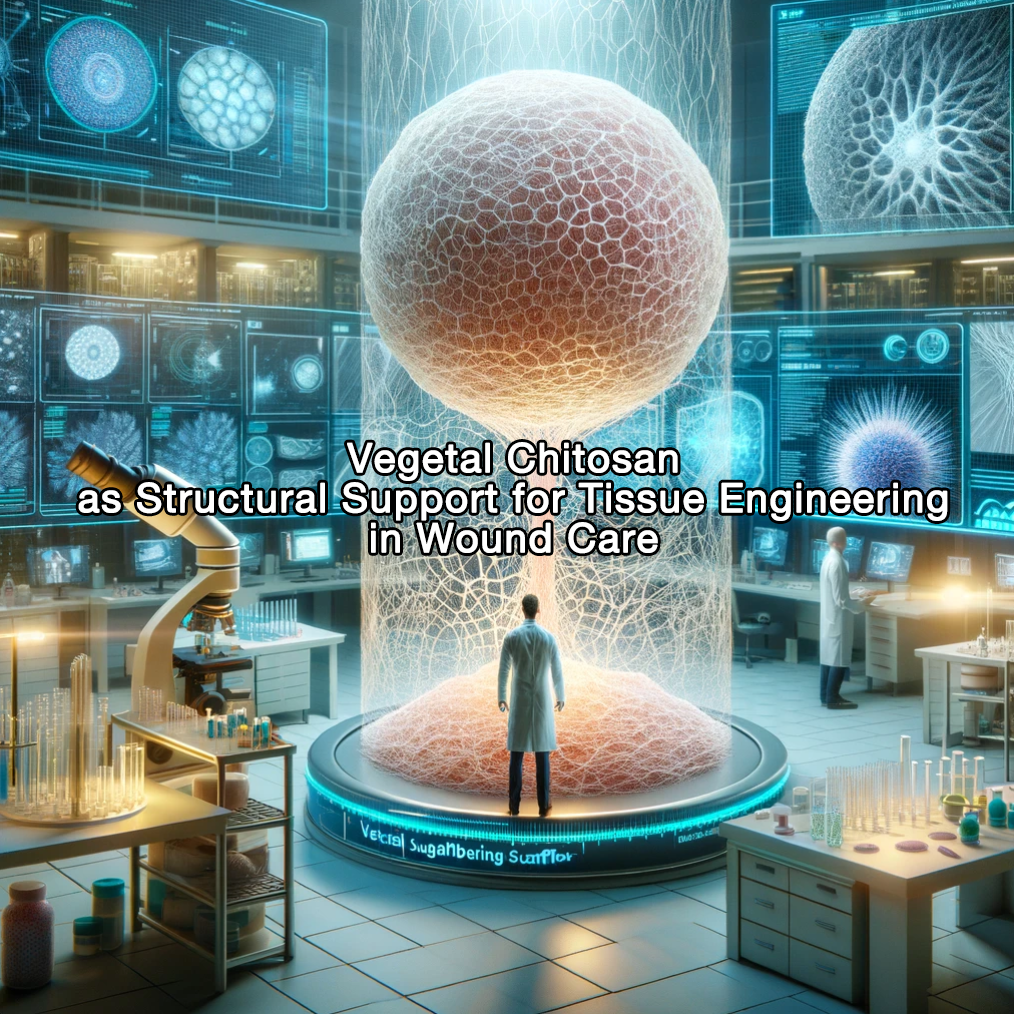

- Structural Support for Tissue Engineering: In more advanced applications, chitosan can be used as a scaffolding material in tissue engineering. Its structural properties help in supporting new tissue growth, making it suitable for regenerative medicine applications related to wound healing.

In conclusion, vegetal chitosan offers a unique combination of benefits and functions that make it highly suitable for wound care applications. Its ability to promote healing and prevent infection while being biocompatible and biodegradable aligns well with the needs of effective wound management.

4. What the common forms of vegetal chitosan used in wound care?

Vegetal chitosan can be processed into several forms for use in wound care, each suited to different types of wounds and treatment goals.

Creating formulations using vegetal chitosan for wound care products involves carefully balancing the amount of chitosan with other ingredients to achieve the desired properties such as gel strength, flexibility, absorbency, and antimicrobial activity. Here are some of the most common forms and its formulation suggestions and application methods for each type of chitosan-based product used in wound care, including typical chitosan ratios:

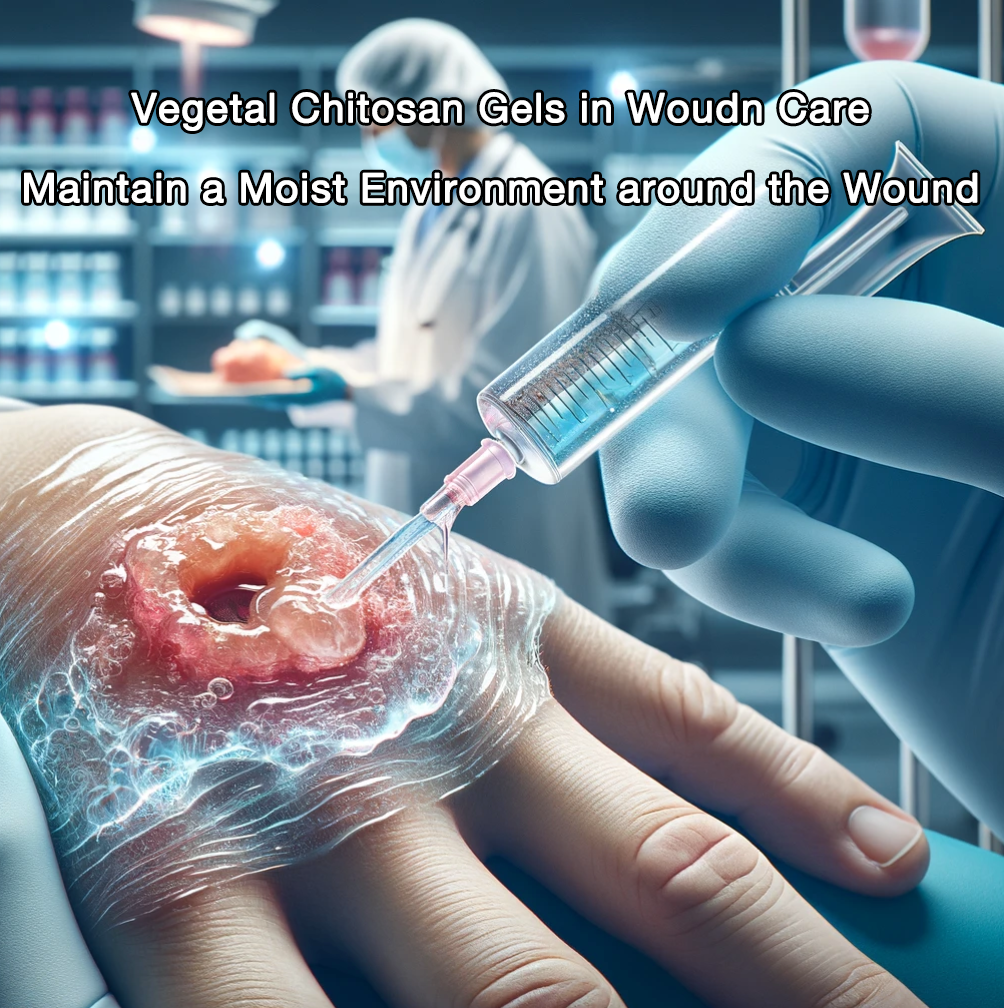

- Chitosan Gels: These are hydrogels made from chitosan that are highly absorbent and can maintain a moist environment around the wound. Chitosan gels are particularly useful for burns, ulcers, and other exuding wounds because they can absorb exudate while releasing antimicrobial agents.

- Chitosan Ratio: Generally, 1% to 2% chitosan dissolved in a suitable aqueous acidic solution (such as acetic acid or lactic acid) to solubilize the chitosan.

- Formulation: Add glycerin or a similar humectant to prevent drying out, along with preservatives to enhance shelf life. For enhanced antimicrobial properties, incorporate silver sulfadiazine or other antimicrobial agents.

- Application: Cleanse the wound area, apply the gel directly to the wound, and cover with a secondary dressing if necessary. Change daily or as needed based on the wound’s exudation.

- Suitable Chitosan Type: Chitosan Hydrochloride is often preferred for gel formulations because it is highly soluble in water, which facilitates easier preparation of gels without the need for acidic conditions that might irritate the skin. Carboxymethyl Chitosan is also a good choice due to its enhanced solubility at neutral and slightly basic pH levels, making it more comfortable for wound application.

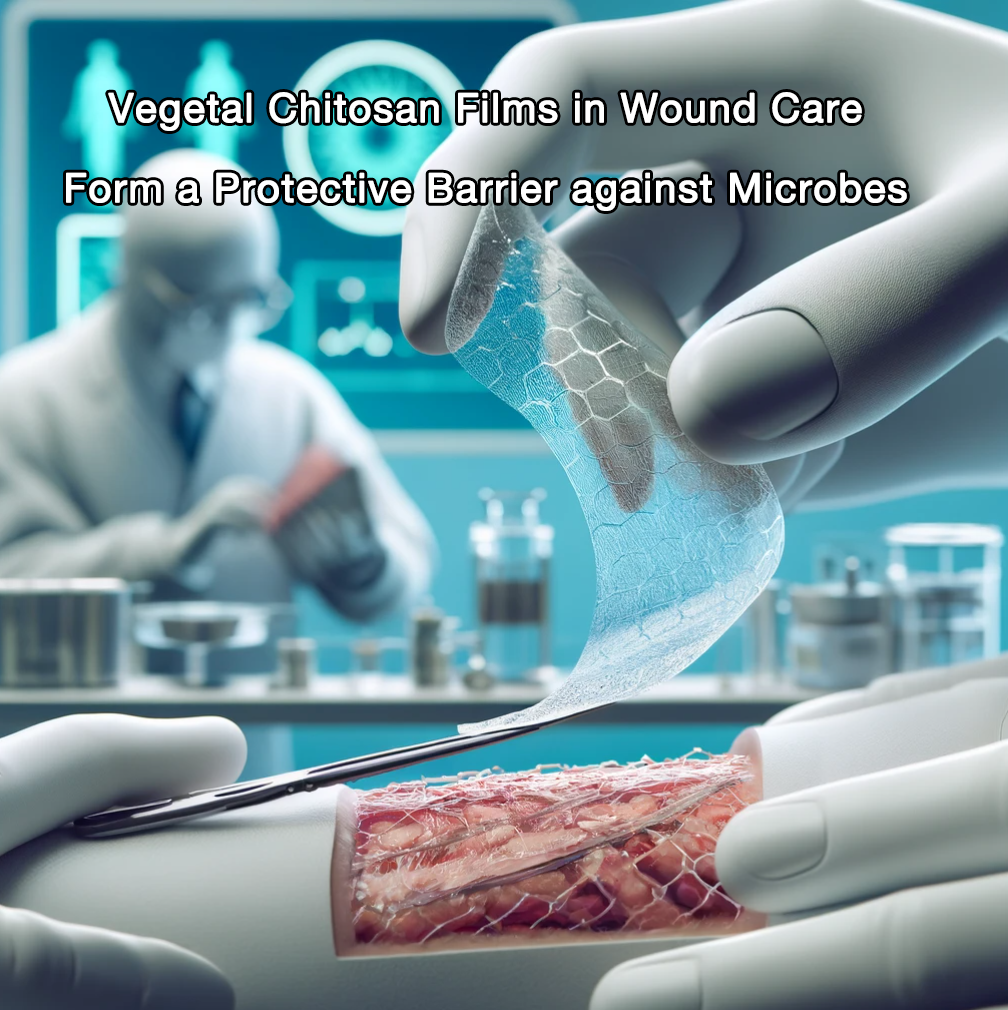

- Chitosan Films: Thin, flexible films made from chitosan can be applied directly to the wound site. These films form a protective barrier against microbes and help maintain the wound’s moisture balance. They are often used for superficial cuts and abrasions.

- Chitosan Ratio: Typically around 1% to 3% chitosan in a solvent mixture, which can be cast and air-dried to form films.

- Formulation: Plasticizers like polyethylene glycol can be added to improve flexibility. Medications or growth factors can also be incorporated into the film.

- Application: Apply the film directly to the cleansed wound. It can stay on the wound for several days depending on the healing environment and the type of wound.

- Suitable Chitosan Type: Acid-Soluble Chitosan works well for films as it forms strong, flexible films under acidic conditions. However, Carboxymethyl Chitosan can also be used to create films that are more flexible and less pH-dependent, which may be gentler on sensitive wound areas.

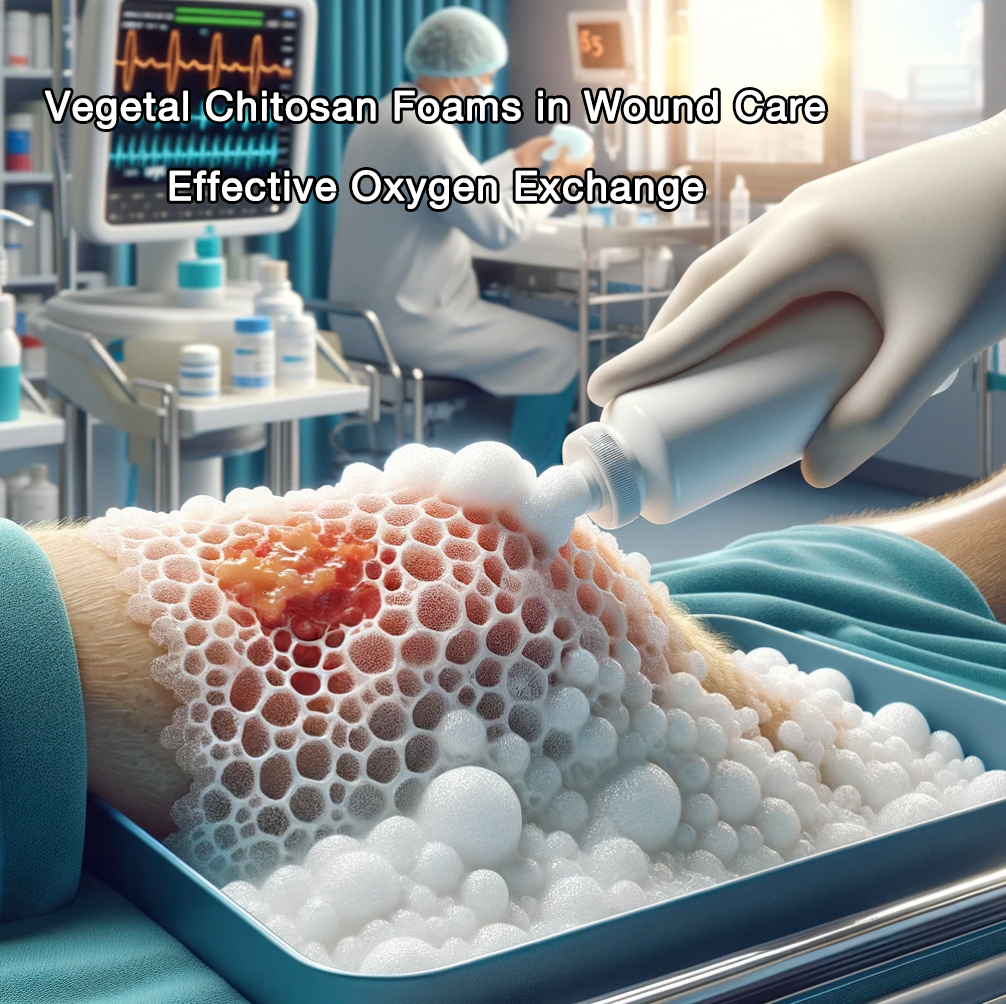

- Chitosan Foams: Foams are another common form of chitosan used in wound dressing. They are soft, highly absorbent, and can be used on a variety of wound types, including those with significant exudate. The porous nature of the foam also allows for effective oxygen exchange, which is crucial for wound healing.

- Chitosan Ratio: Around 1% to 4% chitosan, used with a foaming agent or incorporated into a polymeric matrix that can expand and set into a foam structure.

- Formulation: Include a blowing agent for the foam structure and other polymers to enhance structural integrity and absorbency.

- Application: Place the foam dressing over the wound after thorough cleaning. Suitable for high-exudate wounds, change based on saturation.

- Suitable Chitosan Type: Chitosan Hydrochloride is suitable because of its solubility, which facilitates foaming processes. The solubility helps in uniform incorporation of air or gas bubbles, essential for creating a consistent foam structure.

- Chitosan Fibers: These can be woven into bandages or dressings. Chitosan fibers are useful for their structural integrity and versatility. They can be used to pack or cover wounds, providing structural support and promoting healing.

- Chitosan Ratio: Chitosan fibers are typically created from solutions with higher chitosan concentrations, around 2% to 5%.

- Formulation: The fibers may be spun alone or with other biocompatible materials to enhance tensile strength and flexibility.

- Application: Can be used as part of composite dressings or alone, directly applied to the wound, suitable for packing or wrapping.

- Suitable Chitosan Type: Acid-Soluble Chitosan is typically used for fibers because it can be easily spun into fibers from its acidic solution form. The process involves extruding chitosan through small nozzles into a coagulation medium, forming stable fibers.

- Chitosan Sponges: Similar to foams, chitosan sponges have a highly porous structure that can absorb a large amount of wound exudate. They are particularly useful in managing deep wounds where absorption and maintaining a moist healing environment are critical.

- Chitosan Ratio: About 1% to 3% chitosan, often combined with a cross-linking agent to form a sponge structure.

- Formulation: Cross-linking agents such as glutaraldehyde (use cautiously due to toxicity concerns) or safer alternatives like genipin can be used. Antimicrobial agents can also be added.

- Application: Ideal for deep wounds; place directly into the wound cavity after cleaning. Change based on exudate absorption.

- Suitable Chitosan Type: Chitosan Hydrochloride and Acid-Soluble Chitosan are both effective for sponges due to their ability to form highly absorbent matrix structures when freeze-dried or cross-linked. The choice between these types might depend on the desired rate of biodegradability and mechanical properties.

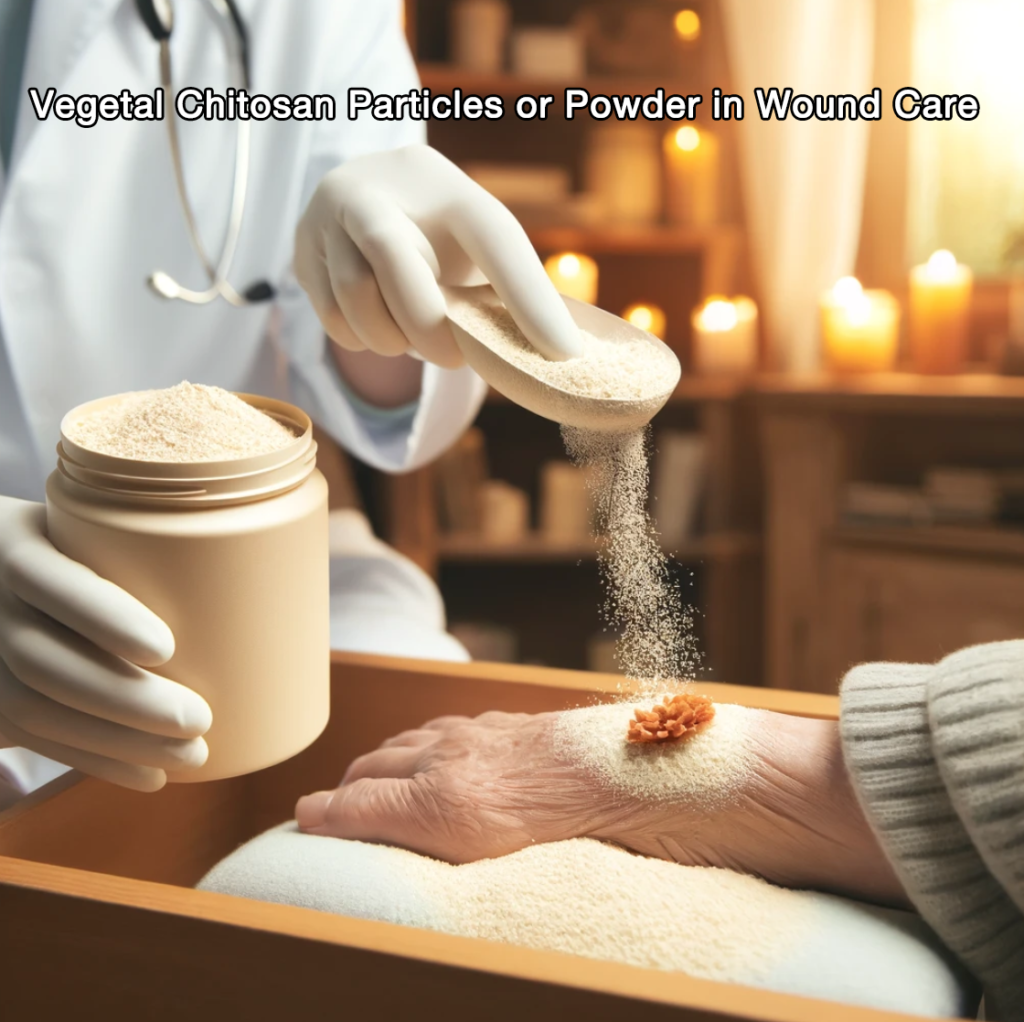

- Chitosan Particles or Powders: These can be sprinkled directly onto wounds or used to create impregnated dressings. They are beneficial for delivering drugs or other bioactive agents directly into the wound bed.

- Chitosan Ratio: High-purity chitosan ground to fine powders, concentrations can vary widely based on the desired application.

- Formulation: Can be mixed with other powdery substances to enhance adherence, absorbency, or antimicrobial activity.

- Application: Sprinkle directly on the wound after thorough cleaning, covered with a secondary dressing.

- Suitable Chitosan Type: Chitosan Oligosaccharide is an excellent choice for powders and particles because of its lower molecular weight, which allows for quicker solubility and absorption. It also facilitates easier application as a powder due to its finer particle size compared to other forms of chitosan.

Each of these forms leverages the inherent properties of chitosan, such as biocompatibility, antimicrobial activity, and biodegradability, making them highly effective in various aspects of wound care.

General Tips for Formulation

- pH adjustment is crucial as chitosan only dissolves in acidic conditions and the final product’s pH should be suitable for application on skin (close to neutral).

- Sterilization methods must be considered to ensure safety without degrading chitosan’s properties.

- Stability and compatibility tests should be performed especially when other active ingredients are included.

These guidelines provide a basic framework for developing chitosan-based wound care products, but detailed formulation development would require experimental validation and regulatory compliance checks, particularly for products intended for medical use.

Additional Considerations for Chitosan Types to Choose

- Carboxymethyl Chitosan generally enhances water solubility and biocompatibility across all forms, and can be particularly beneficial in creating products intended for sensitive or highly absorptive applications.

- Chitosan Hydrochloride offers better solubility in neutral pH conditions compared to traditional acid-soluble chitosan, making it suitable for formulations that require less acidic environments.

The selection of the type of chitosan for each form of wound care product is critical, as the chemical modifications and physical properties of different chitosan derivatives can greatly influence the effectiveness, usability, and comfort of the final product.

Choosing the right type of chitosan is crucial for maximizing the effectiveness of the wound care product, and these choices should be guided by the specific application needs, desired properties of the final product, and the patient’s comfort and safety. Each chitosan derivative brings unique properties that can be leveraged in different forms of wound care products.

5. What is the flowchart of vegetal chitosan processing?

The production process of plant chitosan is mainly obtained by extracting raw materials (mushrooms, Aspergillus niger), deproteinizing with dilute acid or alkali, deacetylating, drying, etc.

Here is a simplified flowchart of the production process of vegetal chitosan for your reference.

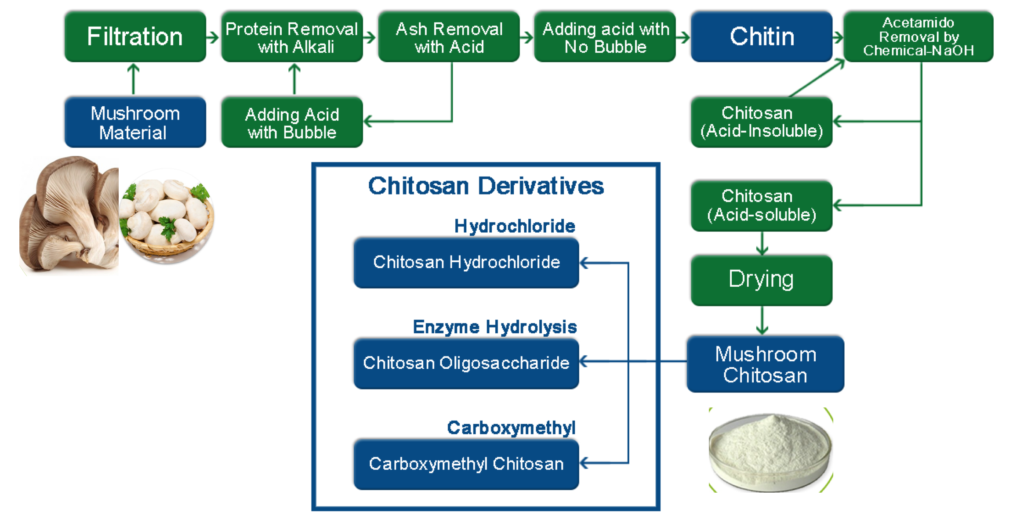

The flowchart of mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

- Starting Material: The process begins with mushroom material as the source.

- Filtration: The mushroom material undergoes a filtration process.

- Protein Removal: Proteins are then removed from the filtered material using an alkali solution.

- Ash Removal: Ash content is subsequently removed with acid.

- Chitin Extraction:

- Acid is added without bubbles to proceed to the next stage.

- Chitin is extracted, which is not soluble in acid.

- An acetylation step removes the acetyl groups from the chitin using sodium hydroxide (NaOH), converting it into chitosan, which is soluble in acid.

- Drying: The acid-soluble chitosan is then dried to produce the final mushroom chitosan product, showcased as a white powder.

- Chitosan Derivatives: Parallel to the drying process, there is a branch leading to the production of various chitosan derivatives:

- Chitosan Hydrochloride: Chitosan converted into its hydrochloride form.

- Enzyme Hydrolysis: Produces chitosan oligosaccharide through enzymatic hydrolysis.

- Carboxymethyl Chitosan: Derived through the carboxymethylation of chitosan.

The flowchart depicts a methodical approach to converting mushroom material into various forms of chitosan, focusing on the purification and chemical modification steps necessary to achieve different chitosan-based products for use in various applications.

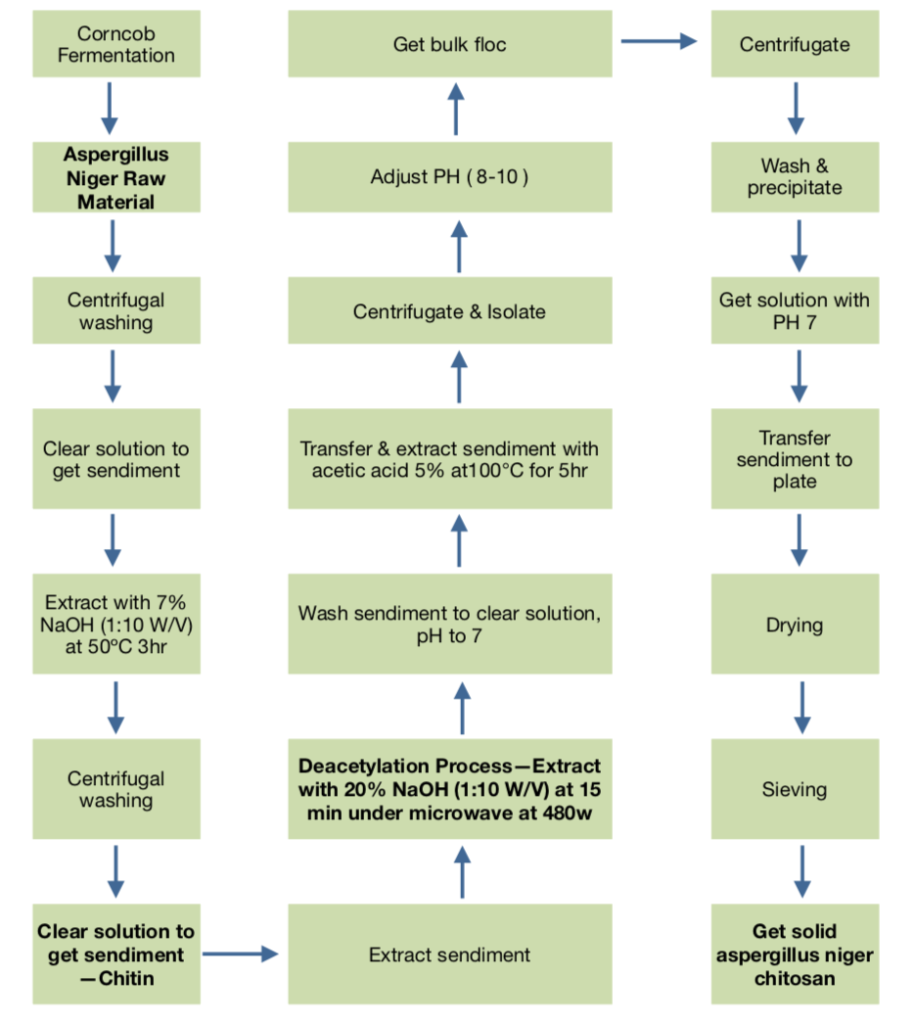

The flowchart of aspergillus niger chitosan outlines the process for extracting chitosan from Aspergillus niger, a type of fungus. Here’s a step-by-step summary of the key points:

- Starting Material: Aspergillus niger is cultured through a fermentation process using corn.

- Extraction:

- The fungal biomass undergoes a bulk flocculation.

- This is followed by centrifugation to separate the components.

- The pH of the resulting material is adjusted to alkaline conditions (pH 8-10).

- Another round of centrifugation and isolation occurs.

- The pH is adjusted back to neutral (pH 7), and the sediment is washed and precipitated.

- The sediment is then extracted with 5% acetic acid at 100°C for five hours to get the clear solution.

- It is washed again to achieve a clear solution with a neutral pH.

- Chitin Production:

- The clear solution is treated with 7% sodium hydroxide (NaOH) at a ratio of 1:10 (W/V) at 50°C for three hours.

- Centrifugal washing follows, resulting in the production of chitin as a clear solution to get the sediment.

- Deacetylation:

- The sediment undergoes the deacetylation process. It’s treated with 20% NaOH at a ratio of 1:10 (W/V) and heated in a microwave at 480W for 15 minutes.

- This step is crucial to convert chitin into chitosan by removing acetyl groups.

- Final Steps:

- The final sediment, which is now deacetylated chitin or chitosan, is extracted.

- It undergoes drying, followed by sieving to achieve the desired particle size.

- End Product: The final product is solid Aspergillus niger chitosan.

This process includes several steps involving pH adjustment, centrifugation, chemical treatments, and heating, which are critical to ensuring the purity and quality of the chitosan extracted from Aspergillus niger.

6. In summary of vegetal chitosan in wound care

Vegetal chitosan, derived from sources like oyster mushrooms and Aspergillus niger, has emerged as a highly effective material for wound care applications due to its biocompatibility, biodegradability, and intrinsic antimicrobial properties.

Its ability to form films, gels, foams, fibers, sponges, and particles or powders makes it extremely versatile in addressing different types of wounds.

Chitosan facilitates rapid hemostasis, accelerates tissue regeneration by promoting collagen synthesis and granulation tissue formation, and helps manage wound exudates through its superior moisture-absorbing capabilities.

These properties not only enhance the healing process but also reduce the risk of infection, making chitosan a valuable component in advanced wound care solutions.

The use of chitosan in wound care is tailored through various formulations, depending on the specific needs of the wound environment.

Chitosan gels are ideal for keeping wounds moist, while films provide a protective barrier. Foams and sponges are suited for highly exudative wounds, absorbing fluids and maintaining optimal conditions for healing. Fibers can be used to pack or wrap wounds, offering structural support.

Each form of chitosan can be adjusted in terms of viscosity and concentration to optimize its effectiveness, demonstrating the adaptability and the potential of vegetal chitosan in improving wound management practices significantly.