1. What is vegetal chitosan?

Chitosan is a natural biopolymer that is primarily derived from chitin, which is the second most abundant natural polysaccharide after cellulose. Chitin is commonly found in the exoskeletons of crustaceans like crabs, shrimps, and lobsters, as well as in the cell walls of certain fungi like mushroom, aspergillus niger.

Structure and Properties:

- Chemical Structure: Chitosan is obtained by deacetylating chitin. This process involves removing acetyl groups from chitin, resulting in a polymer that has free amine groups.

- Solubility: Unlike chitin, chitosan is soluble in acidic to neutral solutions, making it more versatile for various applications.

- Biocompatibility and Biodegradability: Chitosan is known for its excellent biocompatibility and biodegradability. It’s non-toxic and can be broken down by natural biological processes.

Chitosan, sometimes known as deacetylated chitin, is a natural polycationic linear polysaccharide derived from partial deacetylation of chitin. Chitin is the structural element in the exoskeleton of insects, crustaceans (mainly shrimps and crabs shell), and cell walls of fungi (oyster mushroom, agaricus bisprous and aspergillus niger), and also is the second most abundant natural polysaccharide after cellulose.

Chitosan, a natural polysaccharide prepared of fungal origin, is initially extracted and purified from reliable and abundant food or biotechnological fungal sources such as Agaricus bisporus or Aspergillus niger.

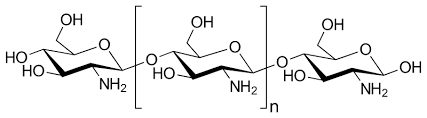

Chitosan is composed of glucosamine sugar units (deacetylated units) and N-acetyl-D-glucosamine units (acetylated units) interconnected by ß→(1.4) type linkages.

Uses and Applications:

- Medical and Pharmaceutical Fields: Due to its biocompatibility and non-toxic nature, chitosan is used in wound healing, drug delivery systems, and as a biomaterial in tissue engineering.

- Water Treatment: Its ability to bind with heavy metals and other contaminants makes it useful in water purification and treatment processes.

- Agriculture: As a natural biostimulant and elicitor, chitosan is used to enhance plant growth and provide resistance against pathogens.

- Food Industry: It’s used as a food additive for its antimicrobial properties, and as an edible film or coating to enhance the shelf life of perishable food products.

- Cosmetics and Personal Care: In this realm, it finds use as a thickener, moisturizer, and film-forming agent, particularly in hair and skin care products.

Chitosan has been widely used in various fields, including wine, pharmaceuticals, dietary supplement, medicine, agriculture, and food industries, due to its biocompatibility, biodegradability, and non-toxicity. In recent years, researchers have investigated the use of vegetal chitosan, which is derived from fungal or plant sources, as a sustainable alternative for use in wine applications.

Variants:

- Traditional Chitosan: Traditionally sourced from marine crustaceans.

- Vegetal Chitosan: Derived from fungal sources, offering an alternative for those seeking non-animal derived products.

In summary, chitosan’s versatility, biodegradability, and non-toxic nature make it a valuable material across various industries, from healthcare to cosmetics. Its ability to be derived from non-animal sources also makes it an appealing option for vegetarian and vegan-friendly products.

2. What are the advantages of vegetal chitosan?

Vegetal chitosan, also known as fungal chitosan or mycelium chitosan, is a type of chitosan derived from the cell walls of fungi (mushroom and aspergillu niger). It has several advantages over traditional chitosan derived from shellfish, including:

- 1. Vegan and vegetarian-friendly: Vegetal chitosan is an excellent alternative for individuals who avoid animal-based products, such as those who follow a vegan or vegetarian lifestyle.

- 2. Allergen-free: Traditional chitosan is derived from shellfish, which can cause allergic reactions in some people. Vegetal chitosan does not contain any shellfish-derived ingredients, making it an allergen-free option.

- 3. Purer: Vegetal chitosan is often considered to be purer than traditional chitosan because it is derived from a single source, whereas traditional chitosan can be contaminated with other shellfish-related substances.

- 4. Better solubility: Vegetal chitosan is more soluble than traditional chitosan, which makes it easier to incorporate into various applications such as cosmetics, pharmaceuticals, wine and food.

- 5. Improved bioavailability: Some studies have suggested that vegetal chitosan has a higher bioavailability compared to traditional chitosan, which means that it can be absorbed and utilized more effectively by the body.

Overall, vegetal chitosan offers several advantages over traditional chitosan, making it an attractive alternative for individuals and industries looking for a vegan, allergen-free, and more effective chitosan source.

3. What are the benefits & functions of vegetal chitosan in water treatment?

Vegetal chitosan derived from sources like mushrooms and Aspergillus niger fungi presents unique benefits and functions in water treatment, primarily due to its natural properties and sustainable origins. Here are some of the key benefits and functions:

Benefits of vegetal chitosan in water treatment

- Biodegradability and Eco-friendliness: Vegetal chitosan is biodegradable and derived from renewable resources, making it an environmentally friendly alternative to synthetic chemicals.

- Non-Toxicity: Being of natural origin, vegetal chitosan is non-toxic and safe for use in various applications, including potable water treatment, without introducing harmful residues.

- Antimicrobial Properties: Vegetal chitosan naturally inhibits the growth of bacteria and other pathogens, which enhances the microbial safety of treated water and extends its storage life.

Functions of vegetal chitosan in water treatment

- Heavy Metal Removal: Chitosan efficiently binds with heavy metals (like lead, arsenic, and cadmium) in water, facilitating their removal through processes such as chelation or ion exchange.

- Flocculation and Coagulation: It acts as a flocculant, causing suspended particles to aggregate into larger clumps that settle out of the water, thereby clarifying turbid water sources.

- Oil and Grease Removal: Vegetal chitosan has the ability to adsorb oils, fats, and greases from water, making it ideal for treating industrial effluents and contaminated runoffs.

- Reduction of Phosphates: It assists in reducing phosphate levels in water, which helps prevent eutrophication that can lead to excessive algae growth and other ecological issues in water bodies.

Each of these benefits and functions highlights the versatility and eco-friendly nature of vegetal chitosan in treating and improving water quality.

4. What is the working mechanism of vegetal chitosan used in water-treatment?

Vegetal chitosan works in water treatment through a variety of mechanisms that leverage its natural properties as a biopolymer. Here’s how it functions:

(1). Flocculation and Coagulation

Vegetal chitosan acts as a natural flocculant and coagulant. When added to water, it binds with suspended particles, including sediments, organic materials, and certain microorganisms. The positive charges on the chitosan molecules attract the negatively charged particles typically found in wastewater. This electrostatic attraction causes the particles to clump together into larger aggregates or flocs. These flocs are then large enough to be removed by settling or filtration. This process is crucial in clarifying water and reducing turbidity.

(2). Metal Ion Chelation

Chitosan has excellent chelating properties, allowing it to bind with heavy metal ions such as lead, mercury, and cadmium. The chitosan molecule has active groups like amino and hydroxyl groups that can complex with metal ions, forming stable, non-soluble complexes. This mechanism is highly beneficial for removing heavy metals from industrial wastewater, thereby preventing metal toxicity in aquatic environments.

(3). Adsorption

Apart from flocculation, chitosan is a powerful adsorbent. Its structure contains numerous binding sites that can adsorb and trap various contaminants, including oils, phosphates, and organic pollutants. This property is especially useful for cleaning up oil spills and removing organic compounds that can contribute to chemical oxygen demand (COD) and biological oxygen demand (BOD) in water bodies.

(4). Antimicrobial Activity

Chitosan exhibits natural antimicrobial properties against a range of pathogenic bacteria and fungi. This activity is primarily due to its ability to disrupt microbial cell membranes and precipitate cellular proteins. In water treatment, this property helps in reducing the microbial load, thereby improving the microbiological quality of the treated water.

(5). Biodegradability

As a biopolymer derived from natural sources, vegetal chitosan is fully biodegradable. This attribute ensures that it does not contribute to environmental pollution post-treatment, unlike some synthetic polymers used in similar applications. Its degradation products are non-toxic and can be safely assimilated back into the environment.

The versatility of vegetal chitosan in water treatment makes it an attractive option for a range of applications, particularly where there is a need for an eco-friendly approach that effectively addresses multiple types of water contaminants.

5. What are the forms of vegetal chitosan used in water treatment?

Vegetal chitosan can be used in various forms in water treatment processes, each suited for different applications depending on the specific requirements of the treatment system.

The addition ratio of chitosan in water treatment can vary significantly based on the specific application, the form of chitosan used, and the characteristics of the water being treated. Here’s some common forms in which vegetal chitosan is utilized, along with an overview of typical addition ratios and suitable application areas for each form of chitosan and a guide on which type of chitosan might be suitable for each form based on their characteristics:

- Flakes or Granules: Chitosan flakes or granules are used in bulk for treating large volumes of water. They can be added directly to water where they act as coagulants or flocculants, helping to bind and precipitate suspended solids.

- Addition Ratio: Typically used at concentrations ranging from 1 to 10 mg/L, depending on the turbidity and type of contaminants.

- Application Areas: Useful for large-scale industrial and municipal wastewater treatment facilities where a significant reduction of suspended solids is required.

- Suitable Chitosan Type: Chitosan with a lower viscosity range (20-100 cps) is generally suitable for creating flakes or granules as it can be easily processed and is effective in adsorbing pollutants at these forms.

- Reason: Lower viscosity chitosan can penetrate and coat solids more effectively, enhancing flocculation and sedimentation processes.

- Powder: Chitosan powder is highly effective for quick dispersion in water. This form is particularly useful for precise dosage control in processes where rapid reaction times are needed, such as in the flocculation and sedimentation stages.

- Addition Ratio: Generally used at about 1 to 5 mg/L. The exact dosage can vary based on the specific needs like the presence of heavy metals or organic pollutants.

- Application Areas: Ideal for quick-response scenarios, such as emergency water treatment and smaller-scale applications where rapid dispersion and reaction are needed.

- Suitable Chitosan Type: Acid-soluble chitosan in the range of 100-500 cps. This range provides a good balance between solubility and reactivity, making it ideal for quick dispersion.

- Reason: Medium viscosity helps maintain a good rate of dissolution while being reactive enough for efficient contaminant binding.

- Solution: Chitosan can be dissolved in acid (usually acetic acid) to form a solution that can be easily dosed and mixed into water treatment systems. This form is beneficial for continuous treatment processes and allows for more uniform distribution of the chitosan throughout the water.

- Addition Ratio: Commonly dosed between 0.5 and 5 mg/L, though it might be higher for heavy contaminant loads.

- Application Areas: Suitable for continuous dosing in both industrial process water systems and municipal water treatment plants. It’s especially good for precise control over treatment in fluid systems.

- Suitable Chitosan Type: Chitosan hydrochloride and chitosan oligosaccharide.

- Reason: Both are highly soluble in water. Chitosan hydrochloride is particularly effective in acidic solutions, making it ideal for use in solution form. Chitosan oligosaccharide, being a low molecular weight chitosan, dissolves quickly and acts effectively in solution.

- Beads or Pellets: These are used in filtration processes. Chitosan beads or pellets can be packed into columns where they act as biofilters or adsorbents, removing contaminants like heavy metals and phosphates as water passes through them.

- Addition Ratio: Used primarily in filter systems rather than dosed by concentration. The volume and size of the filter unit determine the amount.

- Application Areas: Perfect for fixed-bed or column filtration systems where water passes through, such as in point-of-use water filters or tertiary treatment stages in wastewater plants.

- Suitable Chitosan Type: Carboxymethyl chitosan and higher viscosity acid-soluble chitosan (500-1000 cps, up to 1500 cps).

- Reason: These types have enough structural integrity to form beads or pellets, which are crucial for use in filtration systems. Carboxymethyl chitosan, due to its modified structure, can also offer enhanced adsorption properties for specific contaminants.

- Composite Materials: Chitosan is often combined with other materials like activated carbon, clay, or other biopolymers to enhance its properties. These composites can be tailored to target specific types of contaminants more effectively, such as heavy metals, dyes, or organic compounds.

- Addition Ratio: Highly variable; depends on the composite material’s intended function and the nature of the target contaminant.

- Application Areas: These are engineered for specific challenges like selective removal of dyes, heavy metals, or organic compounds, often used in industrial wastewater treatments where standard methods fall short.

- Suitable Chitosan Type: Depending on the target contaminant, combinations of acid-soluble chitosan (across all viscosity ranges), chitosan hydrochloride, and carboxymethyl chitosan can be used.

- Reason: The choice depends on the required reactivity and the physical properties needed in the composite material. Lower viscosities may be better for coatings, whereas higher viscosities might be used for structural components.

- Gels: Chitosan gels can be used in specialized applications where slower release or longer interaction times with water are necessary. They can be particularly useful in controlled release scenarios or when a sustained treatment effect is desired.

- Addition Ratio: Like beads, used based on the physical size and capacity of the treatment system rather than concentration.

- Application Areas: Used in controlled-release applications or when treatment requires prolonged contact with water, such as in slow processing industrial wastewater or remediation sites.

- Suitable Chitosan Type: Higher viscosity acid-soluble chitosan (1000-1500 cps) and carboxymethyl chitosan.

- Reason: Higher viscosity chitosan can form stable gels that are suitable for prolonged interaction with water. Carboxymethyl chitosan can be advantageous for its enhanced solubility and chemical modification, allowing for targeted contaminant removal.

Each of these forms allows chitosan to be utilized effectively in different stages and setups of water treatment, making the most of its beneficial properties for purifying water.

The specific addition ratio and the choice of form should be optimized based on laboratory trials and pilot studies to ensure maximum efficiency and cost-effectiveness in a given treatment scenario.

Each application and chitosan type offers specific properties that need to be matched to the water treatment challenge at hand. Experimental testing and pilot trials are often necessary to fine-tune the selection for optimal performance.

6. Which one is more suitable for water treatment, crustacean chitosan or vegetal chitosan?

Choosing between crustacean chitosan and vegetal chitosan for water treatment depends on several factors including effectiveness, cost, environmental considerations, and specific application requirements. Here’s a comparison to help determine which source might be more suitable:

Consideration for Water Treatment

- Effectiveness: Given its higher degree of deacetylation, vegetal chitosan may actually offer stronger binding capabilities for pollutants, which can enhance its efficiency in removing heavy metals and other contaminants from water. This makes it very effective in applications that require precise pollutant management.

- Cost and Availability: Although vegetal chitosan may still be more costly due to cultivation and processing requirements, its effectiveness might justify the higher price, especially in specialized or high-purity applications.

- Environmental and Ethical Considerations: The environmental benefits of vegetal chitosan remain significant. It’s an excellent option for projects prioritizing sustainability and for markets sensitive to the use of animal-derived products.

Application-Specific Suitability

- Water Treatment: Vegetal chitosan, with its higher degree of deacetylation, is particularly suitable for applications requiring high efficiency in contaminant removal, such as in potable water treatment or sensitive ecological areas.

- Market Preferences: The preference for vegetal chitosan might also be stronger in regions or markets where there is a high demand for eco-friendly, vegan, or hypoallergenic products.

Given these points, vegetal chitosan could be more suitable than crustacean chitosan for many water treatment scenarios, especially where performance in pollutant binding and environmental considerations are paramount.

Meanwhile, considering the cost differences and specific properties of each type of chitosan:

- Crustacean Chitosan is often chosen for wastewater treatment in industrial settings primarily due to its lower cost. This makes it a practical option for large-scale applications where vast quantities of water need treatment, and the slightly lower degree of deacetylation is sufficient for the required level of contaminant removal.

- Vegetal Chitosan, with its higher degree of deacetylation, is better suited for applications requiring a higher purity of treated water, such as in swimming pools. Its ability to more effectively bind with contaminants can ensure a cleaner, safer water environment, which is particularly important in public or recreational water systems where human contact is frequent.

This strategic use of different types of chitosan based on the application requirements and budget constraints helps optimize both performance and cost-efficiency in water treatment processes.

7. Which type of chitosan is particularly suitable for the specified water treatment applications?

To provide a comprehensive guideline about which type of chitosan is suitable for each form and their corresponding water treatment application areas, here’s an overview based on their viscosity ranges and chemical forms:

1. Acid-Soluble Vegetal Chitosan

- 20-100cps:

- Suitable Form: Solution or fine powder.

- Application Areas: Suitable for applications requiring rapid reaction and high dispersion, such as drinking water treatment and small-scale water purification systems.

- Reason: This low viscosity facilitates quick dissolution and dispersion in water, allowing for rapid interaction with contaminants. It’s ideal for treating drinking water or small-scale systems where fast and efficient treatment is required to ensure safety and clarity.

- 100-500cps:

- Suitable Form: Powder or solution.

- Application Areas: Ideal for municipal water treatment, pool water purification, and other applications needing moderate to high solubility and effective pollutant removal.

- Reason: A medium viscosity level provides a balance between ease of handling and substantive performance, allowing it to effectively remove a wide range of pollutants. It’s particularly effective in systems where thorough mixing and moderate reaction times are favorable, such as in municipal or recreational water treatment.

- 500-1000cps:

- Suitable Form: gel.

- Application Areas: Useful in industrial wastewater treatment where higher viscosity aids in the flocculation process and in systems requiring sustained interaction with water.

- Reason: Higher viscosity helps in forming robust gels that can interact with water over a longer duration, which is advantageous for industrial applications where continuous or extensive contact is necessary for effective pollutant binding and removal.

2. Acid-Soluble Crustacean Chitosan

- 20-200cps:

- Suitable Form: Solution or fine powder.

- Application Areas: Effective for general wastewater treatment in industries, where low viscosity facilitates quick dispersion and easy mixing.

- Reason: The lower viscosity range allows for easier mixing and faster chemical reactions, making it suitable for industrial wastewater treatment where efficient and straightforward applications are needed.

- 1000cps-1500cps:

- Suitable Form: Beads, pellets, or thick gel.

- Application Areas: Best suited for water treatment scenarios that benefit from slow-release properties, such as in tertiary treatment stages or specialized filtration systems.

- Reason: High viscosity is beneficial for forming beads or pellets used in filtration systems, providing a sustained release or interaction with water. This is ideal for advanced treatment stages where longer contact times can enhance the removal of stubborn or minute contaminants.

3. Chitosan Hydrochloride

- Suitable Form: Solution.

- Application Areas: Highly soluble in water, making it ideal for use in medical, pharmaceutical, and fine chemical industries where precise dosage and rapid solubility are required.

- Reason: This form is highly soluble in water and can be readily absorbed by biological systems, making it ideal for precise dosing in applications that require exact control and immediate action, such as in pharmaceutical and fine chemical water treatment processes.

4. Chitosan Oligosaccharide

- Suitable Form: Solution or fine spray.

- Application Areas: Due to its low molecular weight and high solubility, it’s particularly suitable for applications where quick bioactivity is essential, such as in potable water treatment and in scenarios requiring rapid microbial action.

- Reason: Its low molecular weight enhances its solubility and bioactivity, making it especially effective for rapid microbial inhibition or degradation in potable water systems where safety and quick response are critical.

5. Carboxymethyl Chitosan

- Suitable Form: Beads, pellets, or solution.

- Application Areas: Given its enhanced solubility and chemical stability, it’s useful in more chemically challenging water treatment processes, like removing organic pollutants and heavy metals from highly contaminated industrial effluents.

- Reason: Modified to enhance its solubility and stability in a variety of pH environments, this type is particularly suitable for treating highly contaminated industrial effluents. Its chemical modifications allow it to bind more effectively with organic pollutants and heavy metals, which are often challenging to remove with standard chitosan.

Each type of chitosan and its corresponding form has specific advantages that make it suitable for different water treatment scenarios. The selection of a particular type and form of chitosan should consider factors like the nature of the water to be treated, the specific contaminants present, and the operational requirements of the treatment system.

Moreover, each of these chitosan types brings specific advantages to water treatment processes, leveraging their inherent chemical properties to meet the unique demands of various applications. This strategic use ensures maximum efficiency in contaminant removal and treatment effectiveness.

8. What is the flowchart of vegetal chitosan processing?

The production process of plant chitosan is mainly obtained by extracting raw materials (mushrooms, Aspergillus niger), deproteinizing with dilute acid or alkali, deacetylating, drying, etc.

Here is a simplified flowchart of the production process of vegetal chitosan for your reference.

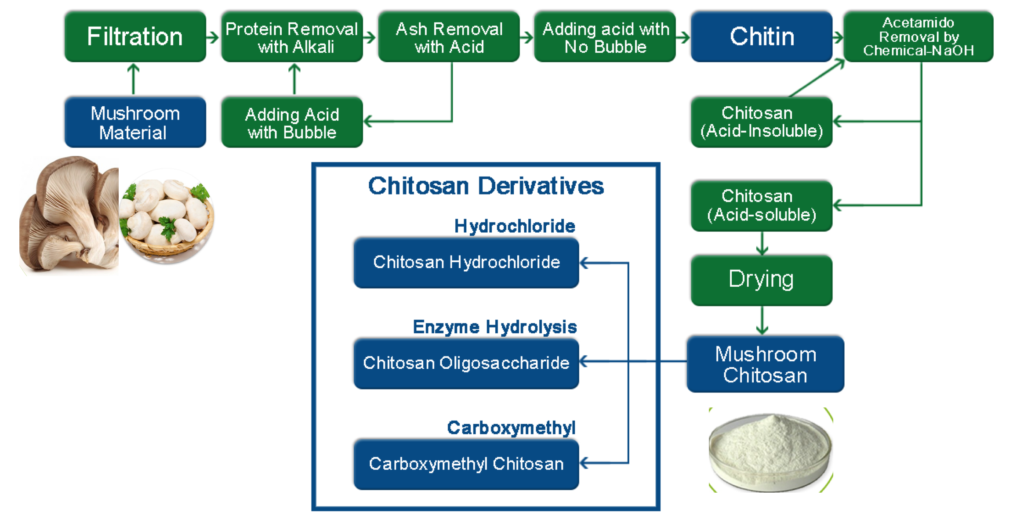

The flowchart of mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

- Starting Material: The process begins with mushroom material as the source.

- Filtration: The mushroom material undergoes a filtration process.

- Protein Removal: Proteins are then removed from the filtered material using an alkali solution.

- Ash Removal: Ash content is subsequently removed with acid.

- Chitin Extraction:

- Acid is added without bubbles to proceed to the next stage.

- Chitin is extracted, which is not soluble in acid.

- An acetylation step removes the acetyl groups from the chitin using sodium hydroxide (NaOH), converting it into chitosan, which is soluble in acid.

- Drying: The acid-soluble chitosan is then dried to produce the final mushroom chitosan product, showcased as a white powder.

- Chitosan Derivatives: Parallel to the drying process, there is a branch leading to the production of various chitosan derivatives:

- Chitosan Hydrochloride: Chitosan converted into its hydrochloride form.

- Enzyme Hydrolysis: Produces chitosan oligosaccharide through enzymatic hydrolysis.

- Carboxymethyl Chitosan: Derived through the carboxymethylation of chitosan.

The flowchart depicts a methodical approach to converting mushroom material into various forms of chitosan, focusing on the purification and chemical modification steps necessary to achieve different chitosan-based products for use in various applications.

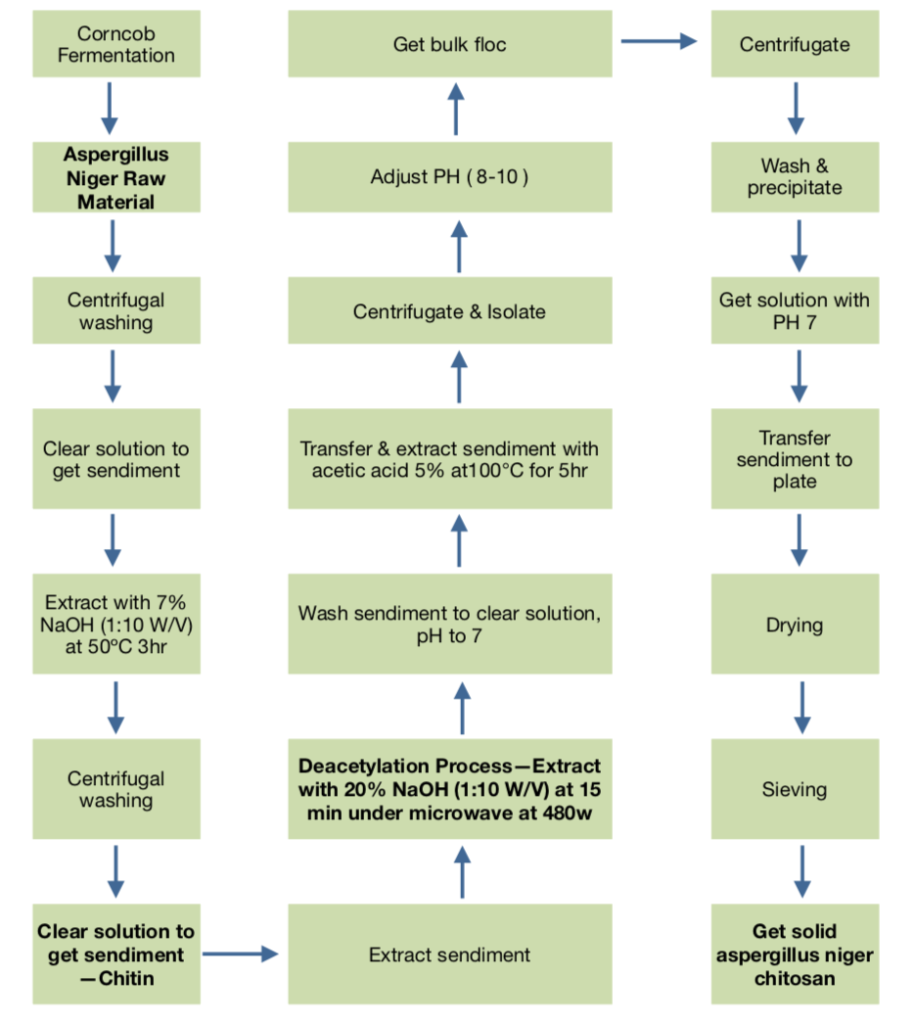

The flowchart of aspergillus niger chitosan outlines the process for extracting chitosan from Aspergillus niger, a type of fungus. Here’s a step-by-step summary of the key points:

- Starting Material: Aspergillus niger is cultured through a fermentation process using corn.

- Extraction:

- The fungal biomass undergoes a bulk flocculation.

- This is followed by centrifugation to separate the components.

- The pH of the resulting material is adjusted to alkaline conditions (pH 8-10).

- Another round of centrifugation and isolation occurs.

- The pH is adjusted back to neutral (pH 7), and the sediment is washed and precipitated.

- The sediment is then extracted with 5% acetic acid at 100°C for five hours to get the clear solution.

- It is washed again to achieve a clear solution with a neutral pH.

- Chitin Production:

- The clear solution is treated with 7% sodium hydroxide (NaOH) at a ratio of 1:10 (W/V) at 50°C for three hours.

- Centrifugal washing follows, resulting in the production of chitin as a clear solution to get the sediment.

- Deacetylation:

- The sediment undergoes the deacetylation process. It’s treated with 20% NaOH at a ratio of 1:10 (W/V) and heated in a microwave at 480W for 15 minutes.

- This step is crucial to convert chitin into chitosan by removing acetyl groups.

- Final Steps:

- The final sediment, which is now deacetylated chitin or chitosan, is extracted.

- It undergoes drying, followed by sieving to achieve the desired particle size.

- End Product: The final product is solid Aspergillus niger chitosan.

This process includes several steps involving pH adjustment, centrifugation, chemical treatments, and heating, which are critical to ensuring the purity and quality of the chitosan extracted from Aspergillus niger.

9. In summary of vegetal chitosan in water treatment

Vegetal chitosan, derived from fungal sources such as mushrooms and Aspergillus niger, represents a breakthrough in eco-friendly water treatment technologies.

With its higher degree of deacetylation compared to traditional crustacean-based chitosan, vegetal chitosan offers superior efficacy in binding and removing a wide range of contaminants, including heavy metals, oils, and phosphates.

This makes it especially valuable in applications requiring high purity water, such as in drinking water systems and swimming pools, where safety and environmental sustainability are paramount.

Furthermore, vegetal chitosan’s biodegradability and non-animal origin make it an ideal choice for sectors looking to meet stringent environmental regulations and appeal to ethically-conscious consumers.

Its ability to function effectively across a spectrum of pH levels and its compatibility with other water treatment agents allow for versatile integration into existing treatment infrastructures.

As industries and municipalities increasingly prioritize green solutions, vegetal chitosan stands out as an efficient, environmentally responsible option for modern water purification needs.

While vegetal chitosan might be less cost-effective compared to crustacean chitosan due to its higher production costs, its superior effectiveness in certain applications and its environmentally friendly profile still make it a compelling choice for specific water treatment scenarios.

These include settings where a higher degree of purity is necessary, or where environmental sustainability and non-animal origin products are prioritized.

Despite its higher price, the demand for vegetal chitosan continues to grow in sectors focused on eco-conscious water purification practices, reflecting its value in meeting rigorous environmental and safety standards.