1. What is vegetal chitosan?

Chitosan is a natural biopolymer that is primarily derived from chitin, which is the second most abundant natural polysaccharide after cellulose. Chitin is commonly found in the exoskeletons of crustaceans like crabs, shrimps, and lobsters, as well as in the cell walls of certain fungi like mushroom, aspergillus niger.

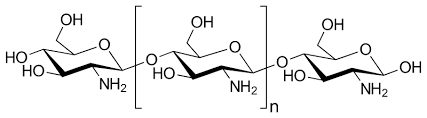

Structure and Properties:

- Chemical Structure: Chitosan is obtained by deacetylating chitin. This process involves removing acetyl groups from chitin, resulting in a polymer that has free amine groups.

- Solubility: Unlike chitin, chitosan is soluble in acidic to neutral solutions, making it more versatile for various applications.

- Biocompatibility and Biodegradability: Chitosan is known for its excellent biocompatibility and biodegradability. It’s non-toxic and can be broken down by natural biological processes.

Chitosan, sometimes known as deacetylated chitin, is a natural polycationic linear polysaccharide derived from partial deacetylation of chitin. Chitin is the structural element in the exoskeleton of insects, crustaceans (mainly shrimps and crabs shell), and cell walls of fungi (oyster mushroom, agaricus bisprous and aspergillus niger), and also is the second most abundant natural polysaccharide after cellulose.

Chitosan, a natural polysaccharide prepared of fungal origin, is initially extracted and purified from reliable and abundant food or biotechnological fungal sources such as Agaricus bisporus or Aspergillus niger.

Chitosan is composed of glucosamine sugar units (deacetylated units) and N-acetyl-D-glucosamine units (acetylated units) interconnected by ß→(1.4) type linkages.

Uses and Applications:

- Medical and Pharmaceutical Fields: Due to its biocompatibility and non-toxic nature, chitosan is used in wound healing, drug delivery systems, and as a biomaterial in tissue engineering.

- Water Treatment: Its ability to bind with heavy metals and other contaminants makes it useful in water purification and treatment processes.

- Agriculture: As a natural biostimulant and elicitor, chitosan is used to enhance plant growth and provide resistance against pathogens.

- Food Industry: It’s used as a food additive for its antimicrobial properties, and as an edible film or coating to enhance the shelf life of perishable food products.

- Cosmetics and Personal Care: In this realm, it finds use as a thickener, moisturizer, and film-forming agent, particularly in hair and skin care products.

Chitosan has been widely used in various fields, including wine, pharmaceuticals, dietary supplement, medicine, agriculture, and food industries, due to its biocompatibility, biodegradability, and non-toxicity. In recent years, researchers have investigated the use of vegetal chitosan, which is derived from fungal or plant sources, as a sustainable alternative for use in wine applications.

Variants:

- Traditional Chitosan: Traditionally sourced from marine crustaceans.

- Vegetal Chitosan: Derived from fungal sources, offering an alternative for those seeking non-animal derived products.

In summary, chitosan’s versatility, biodegradability, and non-toxic nature make it a valuable material across various industries, from healthcare to cosmetics. Its ability to be derived from non-animal sources also makes it an appealing option for vegetarian and vegan-friendly products.

2. What are the advantages of vegetal chitosan?

Vegetal chitosan, also known as fungal chitosan or mycelium chitosan, is a type of chitosan derived from the cell walls of fungi (mushroom and aspergillu niger). It has several advantages over traditional chitosan derived from shellfish, including:

- 1. Vegan and vegetarian-friendly: Vegetal chitosan is an excellent alternative for individuals who avoid animal-based products, such as those who follow a vegan or vegetarian lifestyle.

- 2. Allergen-free: Traditional chitosan is derived from shellfish, which can cause allergic reactions in some people. Vegetal chitosan does not contain any shellfish-derived ingredients, making it an allergen-free option.

- 3. Purer: Vegetal chitosan is often considered to be purer than traditional chitosan because it is derived from a single source, whereas traditional chitosan can be contaminated with other shellfish-related substances.

- 4. Better solubility: Vegetal chitosan is more soluble than traditional chitosan, which makes it easier to incorporate into various applications such as cosmetics, pharmaceuticals, wine and food.

- 5. Improved bioavailability: Some studies have suggested that vegetal chitosan has a higher bioavailability compared to traditional chitosan, which means that it can be absorbed and utilized more effectively by the body.

Overall, vegetal chitosan offers several advantages over traditional chitosan, making it an attractive alternative for individuals and industries looking for a vegan, allergen-free, and more effective chitosan source.

3. What are the benefits & functions of vegetal chitosan in disinfection application?

Vegetal chitosan, derived from sources like mushrooms and Aspergillus niger, offers several benefits and functions when used in disinfection applications:

- Antimicrobial Properties: Vegetal chitosan has strong antimicrobial properties against a wide range of pathogens including bacteria, fungi, and viruses. This makes it an effective agent for disinfection purposes.

- Biodegradability: As a natural biopolymer, vegetal chitosan is biodegradable. This quality makes it environmentally friendly compared to synthetic disinfectants, which can accumulate and cause environmental damage.

- Non-toxicity: Unlike many chemical disinfectants, vegetal chitosan is non-toxic to humans and animals at the concentrations used for disinfection. This makes it safe for use in various settings, including food preservation, water treatment, and surface sanitization.

- Film-Forming Ability: Chitosan can form bioactive films and coatings that can be applied to surfaces for prolonged antimicrobial protection. This is particularly useful for keeping surfaces sterile over time without continuous application of disinfectant.

- Metal Ion Chelation: Chitosan has the ability to chelate metal ions, which can enhance its antimicrobial effectiveness. The presence of chitosan can disrupt microbial cell walls by binding to essential metals required by bacteria and fungi.

- Enhanced Efficacy with pH Sensitivity: Chitosan’s antimicrobial activity can be enhanced in acidic environments, which is beneficial since many disinfection scenarios involve controlled pH conditions.

These properties make vegetal chitosan an attractive option for disinfection in various applications, particularly where environmental impact and human safety are concerns

4. What are the disinfection applications and products that use vegetal chitosan?

Vegetal chitosan, with its natural antimicrobial and biodegradable properties, is versatile and can be integrated into several of the disinfection application areas and product types.

The addition ratio of chitosan and formulation guidelines can also vary widely based on the specific application, desired properties, and regulatory requirements.

Here’s how it can be applied across these various sectors and some general guidelines and typical ratios used in different products and applications:

- Healthcare Facilities:

- Surface Disinfectants: Vegetal chitosan can be used to formulate sprays and wipes that are effective against bacteria and viruses, suitable for cleaning patient rooms and other surfaces.

- Instrument Disinfectants: It can be part of solutions for sterilizing medical instruments, offering a non-toxic and biodegradable alternative to harsh chemicals.

- Addition Ratio: Around 1% to 3% chitosan in the formulation.

- Formulation Guideline: The product should be tested to ensure it does not leave residues that could interfere with healthcare operations. Compatibility with various surface materials is also essential.

- Water Treatment:

- Chemical Disinfectants: Chitosan is useful in water purification systems for binding and neutralizing pathogens and heavy metals, enhancing the quality of drinking water without harsh chemicals.

- Addition Ratio: Typically, 1 to 5 grams per liter of water, depending on the level of contamination and the purity required.

- Formulation Guideline: Chitosan is often used as a flocculant; it helps to agglomerate suspended particles for easier removal. The pH of the water may need to be adjusted to optimize chitosan’s effectiveness, as it performs best in slightly acidic conditions.

- Food and Beverage Industry:

- Food Surface Sanitizers: Chitosan-based sanitizers can be used on food-contact surfaces to inhibit microbial growth, helping maintain hygiene in food processing areas.

- Food Processing Disinfectants: As a natural antimicrobial, chitosan can be used to keep food processing environments sterile and free from contaminants.

- Addition Ratio: About 0.5% to 2% chitosan in solution.

- Formulation Guideline: Chitosan solutions for surface sanitizing should be compatible with food safety standards. Formulations might also include mild acids like acetic acid to enhance antimicrobial efficacy.

- Public and Commercial Areas:

- Air Disinfectants: Integrated into air filtration systems, chitosan can help in capturing and neutralizing airborne pathogens, suitable for places like schools and offices.

- Addition Ratio: Not typically applied as a percentage; instead, chitosan is incorporated into the filter material during manufacturing.

- Formulation Guideline: Ensure the chitosan is properly embedded within the filter media to maintain air flow and filtration efficiency.

- Household Settings:

- Multipurpose Disinfectants: Home cleaning products can include chitosan for its antimicrobial properties, making it ideal for kitchen, bathroom, and general household cleaning.

- Laundry Sanitizers: Chitosan can be added to laundry detergents to help eliminate bacteria and viruses from fabrics during washing.

- Addition Ratio: Usually around 0.5% to 2%.

- Formulation Guideline: Products should be designed to maintain efficacy across a range of surface types and dirt levels. pH and stability tests are crucial to ensure long shelf life.

- Industrial and Manufacturing:

- Industrial Cleaners: Due to its effectiveness and safety, chitosan can be included in cleaners for use in manufacturing environments where non-toxic and eco-friendly solutions are preferred.

- Addition Ratio: Coating solutions might contain 1% to 3% chitosan.

- Formulation Guideline: In textiles, chitosan treatments should be applied so that they bond well with the fabric without affecting its breathability and texture.

- Agriculture and Horticulture:

- Greenhouse Sanitizers: Chitosan can be used to disinfect greenhouse surfaces and equipment, protecting plants from microbial infections.

- Livestock Disinfectants: It can be used in formulations to sanitize animal housing, providing a safe environment for livestock.

- Addition Ratio: Typically around 1% to 2% chitosan.

- Formulation Guideline: Ensure that the chitosan does not negatively affect plant growth; compatibility with various plant species can vary.

General Considerations

- pH Sensitivity: Chitosan’s solubility and effectiveness are pH-dependent, often requiring acidic conditions to function optimally.

- Compatibility: Ensure that chitosan is compatible with other components in the formulation and does not react undesirably.

- Regulatory Compliance: Always consider local regulations regarding the use of biopolymers in consumer and industrial products, especially in food and healthcare industries.

In each of these applications, vegetal chitosan offers a sustainable and effective alternative to traditional chemical disinfectants, aligning with growing demands for environmentally friendly and safe disinfection solutions.

Meanwhile, these ratios and guidelines are starting points. Specific formulations often require thorough testing and optimization to meet the desired performance standards and regulatory requirements.

5. Which type of vegetal chitosan is suitable for the disinfection application & products?

Selecting the right type of vegetal chitosan for a specific application depends on the desired properties and the specifics of the application. Here’s a breakdown of which types might be best suited for the various applications and products:

1. Acid-Soluble Chitosan (Viscosity Range Specifics)

- 20-100 cps: Suitable for applications requiring quick and complete solubility, such as in water treatment and surface sanitizers where rapid action is essential.

- 100-500 cps: This medium viscosity is good for film-forming applications, such as coatings for food preservation or air filters, where a thicker layer might be beneficial for prolonged action.

- 500-1000 cps: Higher viscosity chitosan can be useful in applications where a more substantial gel or layer is beneficial, such as in wound dressings or agricultural sprays that need to adhere to surfaces longer.

2. Chitosan Hydrochloride

- This type is highly soluble in water and useful in applications where low pH environments are not practical. It’s ideal for healthcare applications, including instrument sterilization and surface disinfectants, where compatibility with a range of materials and conditions is necessary.

3. Chitosan Oligosaccharide

- Due to its smaller molecular size and high solubility, chitosan oligosaccharide is particularly effective in applications requiring rapid bioactivity. It is well-suited for water treatment, cosmetics, and potentially as an additive in air filtration systems to quickly neutralize pathogens.

4. Carboxymethyl Chitosan

- This derivative has enhanced solubility across a broader pH range, making it versatile for use in cosmetics and personal care products where a neutral pH is common. It’s also suitable for food surface sanitizers and household cleaners, offering effective microbial control without altering the sensory properties of food or damaging surfaces.

Application Recommendations:

- Water Treatment: Acid-soluble chitosan (20-100 cps) or chitosan hydrochloride for its solubility.

- Food and Beverage Industry: Carboxymethyl chitosan for surface sanitizers, and acid-soluble chitosan (100-500 cps) for coatings.

- Healthcare Facilities: Chitosan hydrochloride for its excellent compatibility and effectiveness.

- Air Filtration: Chitosan oligosaccharide for rapid action and high efficiency.

- Household and Industrial Cleaners: Carboxymethyl chitosan for its versatility and effectiveness in a range of pH environments.

- Textile Treatments: Medium to high viscosity acid-soluble chitosan (100-1000 cps) for durable coatings.

- Agricultural Applications: High viscosity acid-soluble chitosan (500-1000 cps) for prolonged adherence and effectiveness on plants and surfaces. Chitosan oligosaccharide sprays offer a sustainable and effective option for enhancing crop resilience and yield, making them a valuable tool in the arsenal of modern sustainable agriculture.

Each of these types of chitosan has distinct properties that make them suitable for specific applications, and choosing the right one depends on the detailed requirements of the application including environmental conditions, required longevity of action, and regulatory compliance.

6. What are the forms of vegetal chitosan used in disinfection applications?

In disinfection applications, vegetal chitosan can be used in various forms to maximize its antimicrobial properties.

And each form of vegetal chitosan has specific applications where it can be most effective due to its unique properties. Here are some of the most common forms and a breakdown of suitable application areas for each form:

- Chitosan Solutions: These are aqueous solutions where chitosan is dissolved, typically with the aid of acidic agents like acetic acid to ensure solubility. These solutions can be used as sprays or soaks for surface disinfection, including food contact surfaces and medical equipment.

- Surface Disinfectants: Ideal for cleaning and disinfecting surfaces in healthcare settings, schools, and food preparation areas.

- Water Treatment: Used in municipal water systems and pools to remove impurities and microbial contaminants.

- Hand Sanitizers: Often formulated into liquid hand sanitizers for personal hygiene.

- Chitosan Powders: Chitosan in powder form can be applied directly or used to formulate various products such as tablets, powders, or incorporated into other materials. It’s used for water treatment, agricultural sprays, and sometimes in air filters.

- Agricultural Sprays: As a powder, chitosan can be mixed with water and sprayed onto plants to help with disease resistance and growth enhancement.

- Industrial Disinfectants: Powder form can be used to create bulk disinfectant products for large scale industrial cleaning.

- Chitosan Films and Coatings: Chitosan can be used to create thin films or coatings that are applied to surfaces or products. These films are particularly useful in food preservation, where they act as a barrier to microbial contamination and extend the shelf life of perishable goods.

- Food Preservation: Applied as a coating on perishable foods to extend shelf life and prevent microbial growth.

- Medical Coatings: Used on medical devices or implants to prevent bacterial infection and improve biocompatibility.

- Chitosan Gels: Gels made from chitosan are used for wound dressing and skin sanitizing applications because of their ability to form protective barriers and promote healing while providing antimicrobial protection.

- Wound Care: Gels are particularly useful for dressing wounds due to their protective, healing, and antimicrobial properties.

- Cosmetic Products: Used in skincare products for its moisturizing and antimicrobial properties.

- Chitosan Capsules or Tablets: These are used in water treatment applications, where they can be added to water systems to gradually release chitosan, helping to purify the water by binding with impurities and microbial contaminants.

- Water Purification Tablets: Used in portable water purification systems for travelers or in emergency situations.

- Controlled Release Applications: In agricultural settings, slow-release tablets can provide sustained delivery of chitosan to help with plant protection.

- Composite Materials: Chitosan is often combined with other materials to enhance its properties. For example, it can be combined with other natural polymers, nanoparticles, or fibrous materials to be used in filters for air and water purification systems.

- Air Filtration Systems: Composites can be used in HVAC systems to enhance air filtration capabilities.

- Advanced Water Treatment: Used in specialized filters for removing more complex or smaller contaminants from water.

Each form of chitosan has specific application techniques and advantages, depending on the desired disinfection outcome and the properties of the area or product being treated.

And each of these forms of vegetal chitosan leverages its natural antimicrobial and biocompatible properties, making them suitable for a wide range of applications across different sectors.

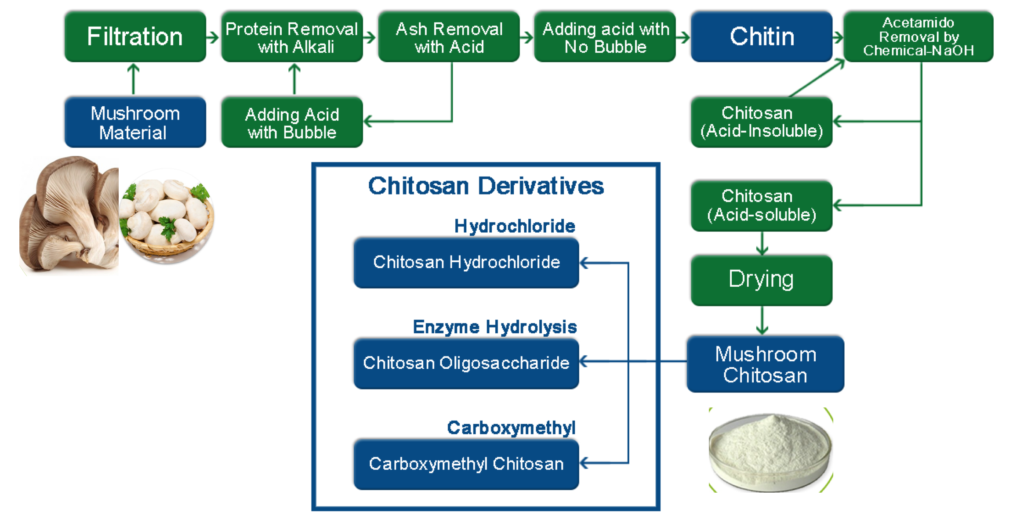

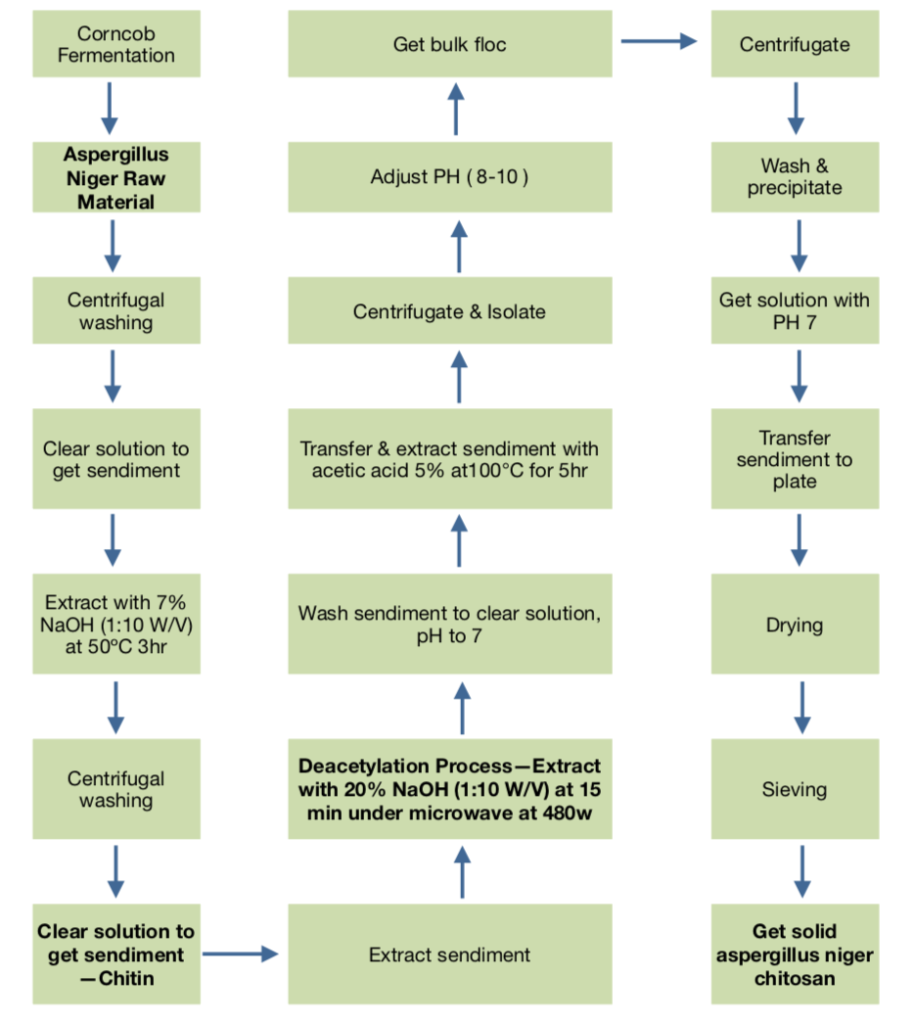

7. What is the flowchart of vegetal chitosan processing?

The production process of plant chitosan is mainly obtained by extracting raw materials (mushrooms, Aspergillus niger), deproteinizing with dilute acid or alkali, deacetylating, drying, etc.

Here is a simplified flowchart of the production process of vegetal chitosan for your reference.

The flowchart of mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

- Starting Material: The process begins with mushroom material as the source.

- Filtration: The mushroom material undergoes a filtration process.

- Protein Removal: Proteins are then removed from the filtered material using an alkali solution.

- Ash Removal: Ash content is subsequently removed with acid.

- Chitin Extraction:

- Acid is added without bubbles to proceed to the next stage.

- Chitin is extracted, which is not soluble in acid.

- An acetylation step removes the acetyl groups from the chitin using sodium hydroxide (NaOH), converting it into chitosan, which is soluble in acid.

- Drying: The acid-soluble chitosan is then dried to produce the final mushroom chitosan product, showcased as a white powder.

- Chitosan Derivatives: Parallel to the drying process, there is a branch leading to the production of various chitosan derivatives:

- Chitosan Hydrochloride: Chitosan converted into its hydrochloride form.

- Enzyme Hydrolysis: Produces chitosan oligosaccharide through enzymatic hydrolysis.

- Carboxymethyl Chitosan: Derived through the carboxymethylation of chitosan.

The flowchart depicts a methodical approach to converting mushroom material into various forms of chitosan, focusing on the purification and chemical modification steps necessary to achieve different chitosan-based products for use in various applications.

The flowchart of aspergillus niger chitosan outlines the process for extracting chitosan from Aspergillus niger, a type of fungus. Here’s a step-by-step summary of the key points:

- Starting Material: Aspergillus niger is cultured through a fermentation process using corn.

- Extraction:

- The fungal biomass undergoes a bulk flocculation.

- This is followed by centrifugation to separate the components.

- The pH of the resulting material is adjusted to alkaline conditions (pH 8-10).

- Another round of centrifugation and isolation occurs.

- The pH is adjusted back to neutral (pH 7), and the sediment is washed and precipitated.

- The sediment is then extracted with 5% acetic acid at 100°C for five hours to get the clear solution.

- It is washed again to achieve a clear solution with a neutral pH.

- Chitin Production:

- The clear solution is treated with 7% sodium hydroxide (NaOH) at a ratio of 1:10 (W/V) at 50°C for three hours.

- Centrifugal washing follows, resulting in the production of chitin as a clear solution to get the sediment.

- Deacetylation:

- The sediment undergoes the deacetylation process. It’s treated with 20% NaOH at a ratio of 1:10 (W/V) and heated in a microwave at 480W for 15 minutes.

- This step is crucial to convert chitin into chitosan by removing acetyl groups.

- Final Steps:

- The final sediment, which is now deacetylated chitin or chitosan, is extracted.

- It undergoes drying, followed by sieving to achieve the desired particle size.

- End Product: The final product is solid Aspergillus niger chitosan.

This process includes several steps involving pH adjustment, centrifugation, chemical treatments, and heating, which are critical to ensuring the purity and quality of the chitosan extracted from Aspergillus niger.

8. Summary of of vegetal chitosan used in disinfection application

Vegetal chitosan, derived from sources like mushrooms and Aspergillus niger, serves as an effective and eco-friendly disinfectant in various applications, leveraging its inherent antimicrobial properties.

Its biodegradable nature makes it particularly appealing in environments where reducing chemical residues is crucial, such as in food processing and healthcare settings.

In the food industry, chitosan is used as a coating for fruits and vegetables, not only to inhibit the growth of pathogens but also to extend shelf life by forming a semi-permeable barrier that controls moisture and gas exchange.

Similarly, in healthcare facilities, vegetal chitosan solutions can be employed to sanitize surfaces, instruments, and even incorporated into hand sanitizers, providing a safe alternative to traditional chemical disinfectants, reducing the risk of allergic reactions and promoting a safer environment for both patients and staff.

Additionally, the versatility of chitosan allows it to be adapted into various forms such as powders, gels, and films, each suitable for specific applications.

For instance, chitosan films are used extensively in wound care products due to their ability to promote healing and prevent infections.

These films form a protective barrier over wounds, optimizing moisture levels, and enhancing the natural healing process while preventing bacterial infections.

In water treatment, chitosan’s effectiveness at binding with pollutants and pathogens is utilized to purify drinking water, making it safer for consumption without the use of harsh chemicals.

Its ability to chelate metals and remove suspended solids from water further underscores its utility in environmental conservation efforts, highlighting chitosan’s role as a sustainable solution in the ongoing challenge of effective yet environmentally conscious disinfection practices.