1. What is vegetal chitosan?

Chitosan is a natural biopolymer that is primarily derived from chitin, which is the second most abundant natural polysaccharide after cellulose. Chitin is commonly found in the exoskeletons of crustaceans like crabs, shrimps, and lobsters, as well as in the cell walls of certain fungi like mushroom, aspergillus niger.

Structure and Properties:

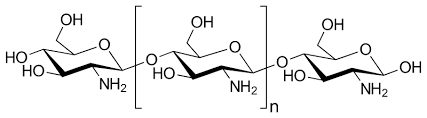

- Chemical Structure: Chitosan is obtained by deacetylating chitin. This process involves removing acetyl groups from chitin, resulting in a polymer that has free amine groups.

- Solubility: Unlike chitin, chitosan is soluble in acidic to neutral solutions, making it more versatile for various applications.

- Biocompatibility and Biodegradability: Chitosan is known for its excellent biocompatibility and biodegradability. It’s non-toxic and can be broken down by natural biological processes.

Chitosan, sometimes known as deacetylated chitin, is a natural polycationic linear polysaccharide derived from partial deacetylation of chitin. Chitin is the structural element in the exoskeleton of insects, crustaceans (mainly shrimps and crabs shell), and cell walls of fungi (oyster mushroom, agaricus bisprous and aspergillus niger), and also is the second most abundant natural polysaccharide after cellulose.

Chitosan, a natural polysaccharide prepared of fungal origin, is initially extracted and purified from reliable and abundant food or biotechnological fungal sources such as Agaricus bisporus or Aspergillus niger.

Chitosan is composed of glucosamine sugar units (deacetylated units) and N-acetyl-D-glucosamine units (acetylated units) interconnected by ß→(1.4) type linkages.

Uses and Applications:

- Medical and Pharmaceutical Fields: Due to its biocompatibility and non-toxic nature, chitosan is used in wound healing, drug delivery systems, and as a biomaterial in tissue engineering.

- Water Treatment: Its ability to bind with heavy metals and other contaminants makes it useful in water purification and treatment processes.

- Agriculture: As a natural biostimulant and elicitor, chitosan is used to enhance plant growth and provide resistance against pathogens.

- Food Industry: It’s used as a food additive for its antimicrobial properties, and as an edible film or coating to enhance the shelf life of perishable food products.

- Cosmetics and Personal Care: In this realm, it finds use as a thickener, moisturizer, and film-forming agent, particularly in hair and skin care products.

Chitosan has been widely used in various fields, including wine, pharmaceuticals, dietary supplement, medicine, agriculture, and food industries, due to its biocompatibility, biodegradability, and non-toxicity. In recent years, researchers have investigated the use of vegetal chitosan, which is derived from fungal or plant sources, as a sustainable alternative for use in wine applications.

Variants:

- Traditional Chitosan: Traditionally sourced from marine crustaceans.

- Vegetal Chitosan: Derived from fungal sources, offering an alternative for those seeking non-animal derived products.

In summary, chitosan’s versatility, biodegradability, and non-toxic nature make it a valuable material across various industries, from healthcare to cosmetics. Its ability to be derived from non-animal sources also makes it an appealing option for vegetarian and vegan-friendly products.

2. What are the advantages of vegetal chitosan?

Vegetal chitosan, also known as fungal chitosan or mycelium chitosan, is a type of chitosan derived from the cell walls of fungi (mushroom and aspergillu niger). It has several advantages over traditional chitosan derived from shellfish, including:

- 1. Vegan and vegetarian-friendly: Vegetal chitosan is an excellent alternative for individuals who avoid animal-based products, such as those who follow a vegan or vegetarian lifestyle.

- 2. Allergen-free: Traditional chitosan is derived from shellfish, which can cause allergic reactions in some people. Vegetal chitosan does not contain any shellfish-derived ingredients, making it an allergen-free option.

- 3. Purer: Vegetal chitosan is often considered to be purer than traditional chitosan because it is derived from a single source, whereas traditional chitosan can be contaminated with other shellfish-related substances.

- 4. Better solubility: Vegetal chitosan is more soluble than traditional chitosan, which makes it easier to incorporate into various applications such as cosmetics, pharmaceuticals, wine and food.

- 5. Improved bioavailability: Some studies have suggested that vegetal chitosan has a higher bioavailability compared to traditional chitosan, which means that it can be absorbed and utilized more effectively by the body.

Overall, vegetal chitosan offers several advantages over traditional chitosan, making it an attractive alternative for individuals and industries looking for a vegan, allergen-free, and more effective chitosan source.

3. What are the benefits & functions of vegetal chitosan in bio-packaging?

Vegetal chitosan, derived from sources like mushrooms & aspergillus niger, offers a variety of benefits and functions in the field of bio-packaging. Here’s a detailed breakdown:

Benefits of Vegetal Chitosan in Bio-Packaging

- Biodegradability: Vegetal chitosan is fully biodegradable, reducing environmental pollution compared to conventional plastic packaging.

- Non-Toxicity: Being derived from natural sources, vegetal chitosan is non-toxic and safe for use in food packaging, posing no harm to consumers or the environment.

- Antimicrobial Properties: Chitosan has inherent antimicrobial properties that help in extending the shelf life of packaged food by inhibiting the growth of bacteria and fungi.

- Barrier Properties: It provides excellent barrier properties against oxygen and oils, crucial for maintaining the quality and freshness of food products.

- Compatibility with Other Materials: Chitosan can be easily combined with other biopolymers, enhancing the mechanical and barrier properties of the resulting bio-packaging material.

Functions of Vegetal Chitosan in Bio-Packaging

- Food Preservation: Utilizes its antimicrobial and antifungal properties to preserve the quality and extend the shelf life of perishable goods, such as fruits, vegetables, and meats.

- Edible Coatings: Vegetal chitosan an be used to create edible films or coatings that directly adhere to the surface of food products, offering additional protection against spoilage and physical damage.

- Controlled Release of Additives: Vegetal chitosan films can incorporate functional additives like antioxidants, flavors, or nutrients, which can be released in a controlled manner to improve food quality and safety.

- Water Vapor Barrier:Acts as an effective barrier to water vapor, helping to maintain the desired moisture content of food products, which is vital for products like baked goods and dried fruits.

- Environmental Impact Reduction:By replacing synthetic plastics with biodegradable chitosan-based materials, the overall environmental impact of packaging waste is significantly reduced.

The use of vegetal chitosan in bio-packaging is a promising development in sustainable packaging solutions, offering both functional benefits and environmental advantages.

4. What are the common forms of vegetal chitosan in bio-packaging?

Vegetal chitosan, derived from fungal sources, is utilized in bio-packaging in several common forms to enhance the functionality and sustainability of packaging materials.

The use of vegetal chitosan, particularly sourced from mushrooms and Aspergillus niger, in various forms of bio-packaging often requires specific formulations to optimize properties like mechanical strength, barrier characteristics, and biodegradability.

Here are some of the primary forms in which vegetal chitosan is used, along with typical ratios and suitable applications and a guide to selecting suitable types and viscosities for various forms of packaging:

- Films and Sheets: Thin films or sheets of chitosan can be formed by solvent casting techniques. These films are transparent and flexible, making them suitable for packaging a variety of goods, especially food products.

- Ratio: Typically, chitosan is used in concentrations of 1% to 3% (w/v) when dissolved in an acidic solvent to form films and sheets.

- Application: These are suitable for wrapping fresh produce, meats, and cheeses, providing a barrier against moisture and microbial growth.

- Suitable chitosan type: Acid-soluble chitosan 20-100cps or chitosan hydrochloride are commonly used due to their good solubility and film-forming ability, allowing for smoother films with uniform thickness.

- Coatings: Chitosan can be applied as a coating solution directly onto the surfaces of food items or onto other packaging materials. This application method enhances the barrier properties against gases and vapors and provides antimicrobial protection.

- Ratio: Coating solutions generally contain chitosan in the range of 1% to 2% (w/v), often combined with plasticizers like glycerol to improve flexibility.

- Application: Directly applied to fruits and vegetables to extend shelf life by reducing spoilage and retaining moisture.

- Suitable chitosan type: Chitosan oligosaccharide and carboxymethyl chitosan are preferred for coatings because they are more soluble and provide better surface adherence.

- Composites:Chitosan is often blended with other biopolymers such as alginate, starch, or cellulose to form composite materials. These composites can improve mechanical strength, barrier properties, and overall functionality of the packaging.

- Ratio: Chitosan is blended with other materials at ratios that can vary widely depending on the desired properties, typically ranging from 1% to 2% chitosan by weight relative to other polymers.

- Application: Used in more structurally demanding packaging solutions like trays and containers for food and electronic items, where additional mechanical strength is required.

- Suitable chitosan type: Acid-soluble chitosan with higher viscosity chitosan (100-500 cps or 500-1000 cps) is often used due to its compatibility with other biopolymers and ability to form robust composites, it can be beneficial for composites as it contributes to the mechanical strength and structural integrity of the material.

- Nanoparticles:Chitosan nanoparticles can be incorporated into bio-packaging to improve barrier properties against UV light and oxygen, or to deliver nutrients or antimicrobials in a controlled-release manner.

- Ratio: Chitosan nanoparticles are usually prepared in concentrations of 0.1% to 1% (w/v), depending on the desired release properties and nanoparticle stability.

- Application: Ideal for active packaging solutions where controlled release of antimicrobials, antioxidants, or other additives is required, such as in packaging for highly perishable goods.

- Suitable chitosan type: Chitosan hydrochloride and chitosan oligosaccharide are excellent choices for nanoparticles due to their strong solubility and ability to form stable nanoparticles.

- Foams:Chitosan-based foams are developed for protective packaging, offering cushioning and protection for delicate items during transport. These foams are lightweight and can be biodegraded after use.

- Ratio: Foam formulations can include chitosan in the range of 1% to 5% (w/v), often with the incorporation of a foaming agent or blowing agent.

- Application: Protective packaging for sensitive items during shipping, offering both cushioning and biodegradability.

- Suitable chitosan type: Carboxymethyl chitosan is a good option for foams because of its enhanced solubility and chemical functionality which can improve foam stability.

These forms enable the utilization of vegetal chitosan’s unique properties, such as biodegradability and antimicrobial activity, making it a valuable component in sustainable packaging solutions.

These ratios and applications are typical, but the specific formulation might vary based on additional factors like the type of food or item being packaged, regulatory requirements, and environmental considerations. Adjustments may be needed based on experimental outcomes or specific industry needs.

These suggestions of suitable chitosan type consider the general properties of each chitosan type and viscosity level, tailored to optimize the form and function of the specific packaging application. Adjustments might be necessary based on specific requirements and experimental feedback.

5. What is the flowchart of vegetal chitosan processing?

The production process of plant chitosan is mainly obtained by extracting raw materials (mushrooms, Aspergillus niger), deproteinizing with dilute acid or alkali, deacetylating, drying, etc.

Here is a simplified flowchart of the production process of vegetal chitosan for your reference.

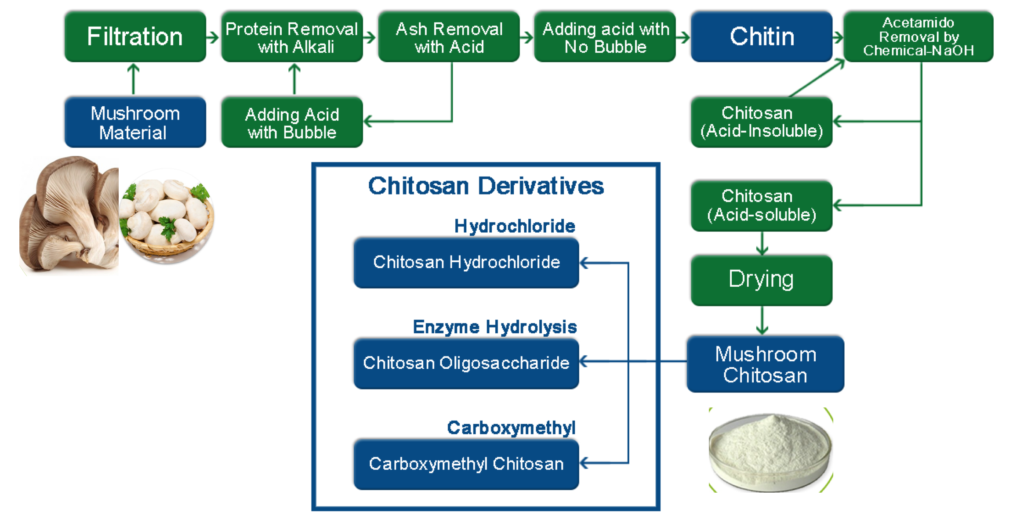

The flowchart of mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

- Starting Material: The process begins with mushroom material as the source.

- Filtration: The mushroom material undergoes a filtration process.

- Protein Removal: Proteins are then removed from the filtered material using an alkali solution.

- Ash Removal: Ash content is subsequently removed with acid.

- Chitin Extraction:

- Acid is added without bubbles to proceed to the next stage.

- Chitin is extracted, which is not soluble in acid.

- An acetylation step removes the acetyl groups from the chitin using sodium hydroxide (NaOH), converting it into chitosan, which is soluble in acid.

- Drying: The acid-soluble chitosan is then dried to produce the final mushroom chitosan product, showcased as a white powder.

- Chitosan Derivatives: Parallel to the drying process, there is a branch leading to the production of various chitosan derivatives:

- Chitosan Hydrochloride: Chitosan converted into its hydrochloride form.

- Enzyme Hydrolysis: Produces chitosan oligosaccharide through enzymatic hydrolysis.

- Carboxymethyl Chitosan: Derived through the carboxymethylation of chitosan.

The flowchart depicts a methodical approach to converting mushroom material into various forms of chitosan, focusing on the purification and chemical modification steps necessary to achieve different chitosan-based products for use in various applications.

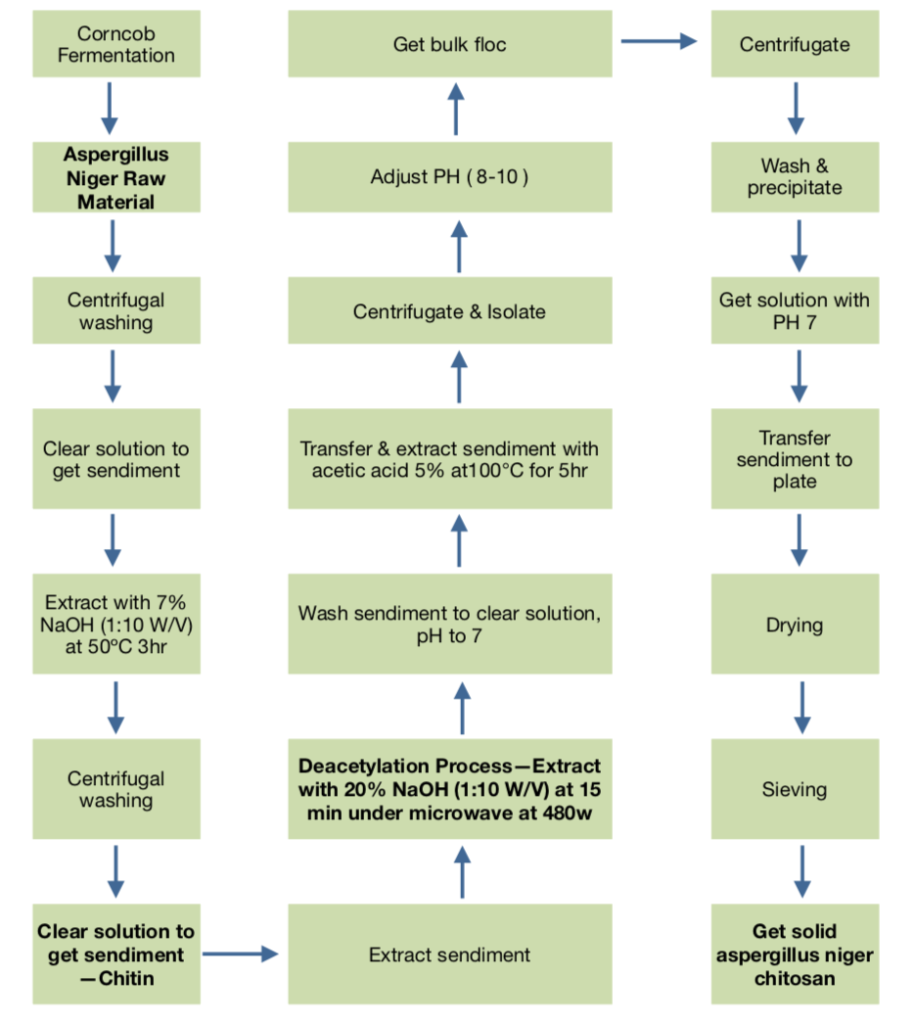

The flowchart of aspergillus niger chitosan outlines the process for extracting chitosan from Aspergillus niger, a type of fungus. Here’s a step-by-step summary of the key points:

- Starting Material: Aspergillus niger is cultured through a fermentation process using corn.

- Extraction:

- The fungal biomass undergoes a bulk flocculation.

- This is followed by centrifugation to separate the components.

- The pH of the resulting material is adjusted to alkaline conditions (pH 8-10).

- Another round of centrifugation and isolation occurs.

- The pH is adjusted back to neutral (pH 7), and the sediment is washed and precipitated.

- The sediment is then extracted with 5% acetic acid at 100°C for five hours to get the clear solution.

- It is washed again to achieve a clear solution with a neutral pH.

- Chitin Production:

- The clear solution is treated with 7% sodium hydroxide (NaOH) at a ratio of 1:10 (W/V) at 50°C for three hours.

- Centrifugal washing follows, resulting in the production of chitin as a clear solution to get the sediment.

- Deacetylation:

- The sediment undergoes the deacetylation process. It’s treated with 20% NaOH at a ratio of 1:10 (W/V) and heated in a microwave at 480W for 15 minutes.

- This step is crucial to convert chitin into chitosan by removing acetyl groups.

- Final Steps:

- The final sediment, which is now deacetylated chitin or chitosan, is extracted.

- It undergoes drying, followed by sieving to achieve the desired particle size.

- End Product: The final product is solid Aspergillus niger chitosan.

This process includes several steps involving pH adjustment, centrifugation, chemical treatments, and heating, which are critical to ensuring the purity and quality of the chitosan extracted from Aspergillus niger.

6. In summary of vegetal chitosan in bio-packaging

Vegetal chitosan sourced from oyster mushrooms and Aspergillus niger is increasingly recognized as a valuable material for bio-packaging due to its sustainable origin and excellent functional properties.

This type of chitosan is obtained from non-animal sources, making it a preferred choice in vegan and environmentally conscious markets.

Its inherent biodegradability and non-toxic nature make it an excellent alternative to synthetic plastics, particularly in the food packaging industry.

The antimicrobial properties of chitosan derived from these sources contribute significantly to extending the shelf life of perishable goods by inhibiting the growth of mold, bacteria, and yeast, which are common spoilage agents in food products.

In the application of bio-packaging, vegetal chitosan can be processed into various forms such as films, coatings, and composites.

Films made from chitosan extracted from oyster mushrooms and Aspergillus niger exhibit good mechanical strength and barrier properties against oxygen and moisture, essential for maintaining the quality and freshness of packaged food.

Moreover, the versatility of chitosan allows for the development of edible coatings that directly adhere to the surface of food items, providing an additional layer of protection while being safe for consumption.

This adaptability not only enhances food safety and reduces waste but also supports the shift towards more sustainable packaging solutions, aligning with global efforts to minimize environmental impact.