Oyster Mushroom Chitosan Oligosaccharide

Oyster Mushroom Chitosan Oligosaccharide

Additional information

| Product Name | Oyster Mushroom Chitosan Oligosaccharide |

|---|---|

| Form | Light yellow powder |

| Source | Oyster mushroom (Scientific name: Pleurotus ostreatus) |

| Cas No. | 148411-57-8 |

| Specification | Water-soluble, Molecular weight ≤5k Da |

| Main Applications | Food, Nasal Spray, Medical Devices, Agriculture etc |

Product Details

What is Oyster Mushroom Chitosan Oligosaccharide?

Oyster Mushroom Chitosan Oligosaccharide, as one derivative of chitosan produced by enzymatic hydrolysis, is a low-molecular-weight, plant-derived biopolymer, specifically designed with a molecular weight of ≤ 5kDa.

Derived from Pleurotus ostreatus (oyster mushrooms), this oligosaccharide offers superior solubility and bioavailability, making it highly effective for various applications, particularly in health, agriculture, cosmetics and food industries.

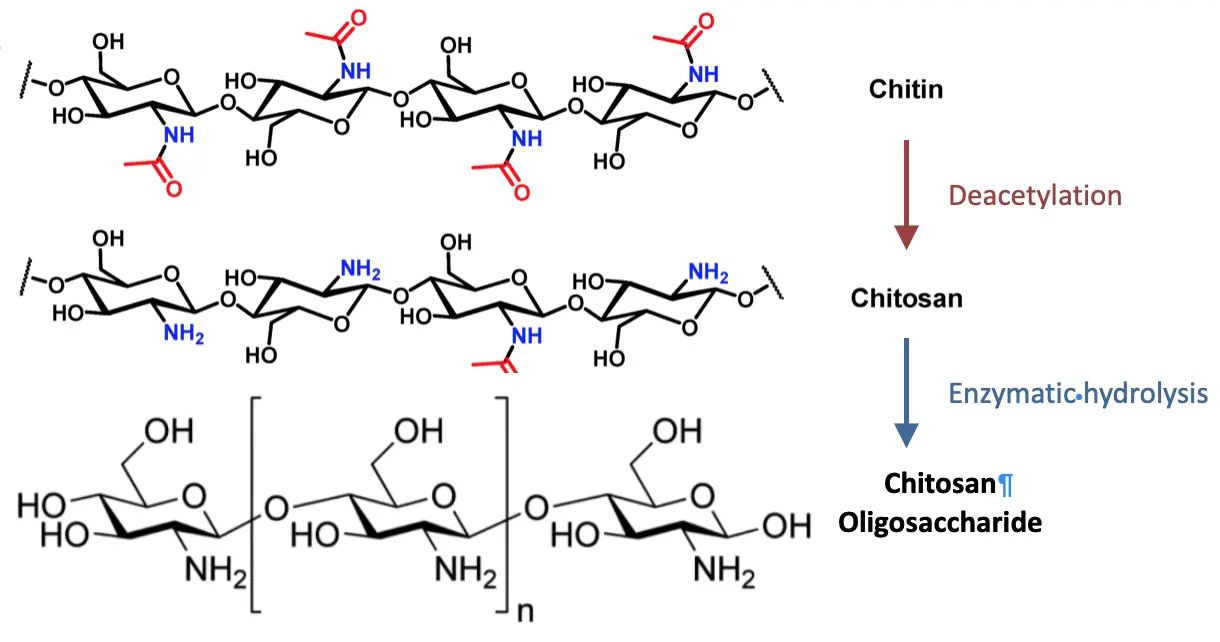

Chitosan Oligosaccharide is a low molecular weight derivative of chitosan, which consists of a series of D-glucosamine units linked by β-(1→4) glycosidic bonds. It retains the beneficial properties of chitosan, such as biodegradability, biocompatibility, and antimicrobial activity, but with enhanced solubility and absorption due to its shorter polymer chains.

CAS Number: CAS No.: 148411-57-8

Chemical Structure:

- Chemical Formula: (C6H11NO4)n(C_6H_{11}NO_4)_n(C6H11NO4)n, where nnn represents the number of glucosamine units in the oligosaccharide.

- The structure of chitosan oligosaccharide consists of a chain of D-glucosamine (GlcN) units, which can vary in length (degree of polymerization). The repeating units are linked by β-(1→4) bonds.

The typical structure can be visualized as:

- [–(C_8H_{13}NO_5)–]n

Where “n” represents the number of repeating units. The degree of polymerization in chitosan oligosaccharides is much lower compared to high-molecular-weight chitosan, resulting in a smaller, more soluble molecule.

This structure allows for enhanced solubility in water and more efficient biological activity, making it suitable for applications such as dietary supplements, pharmaceuticals, and agriculture.

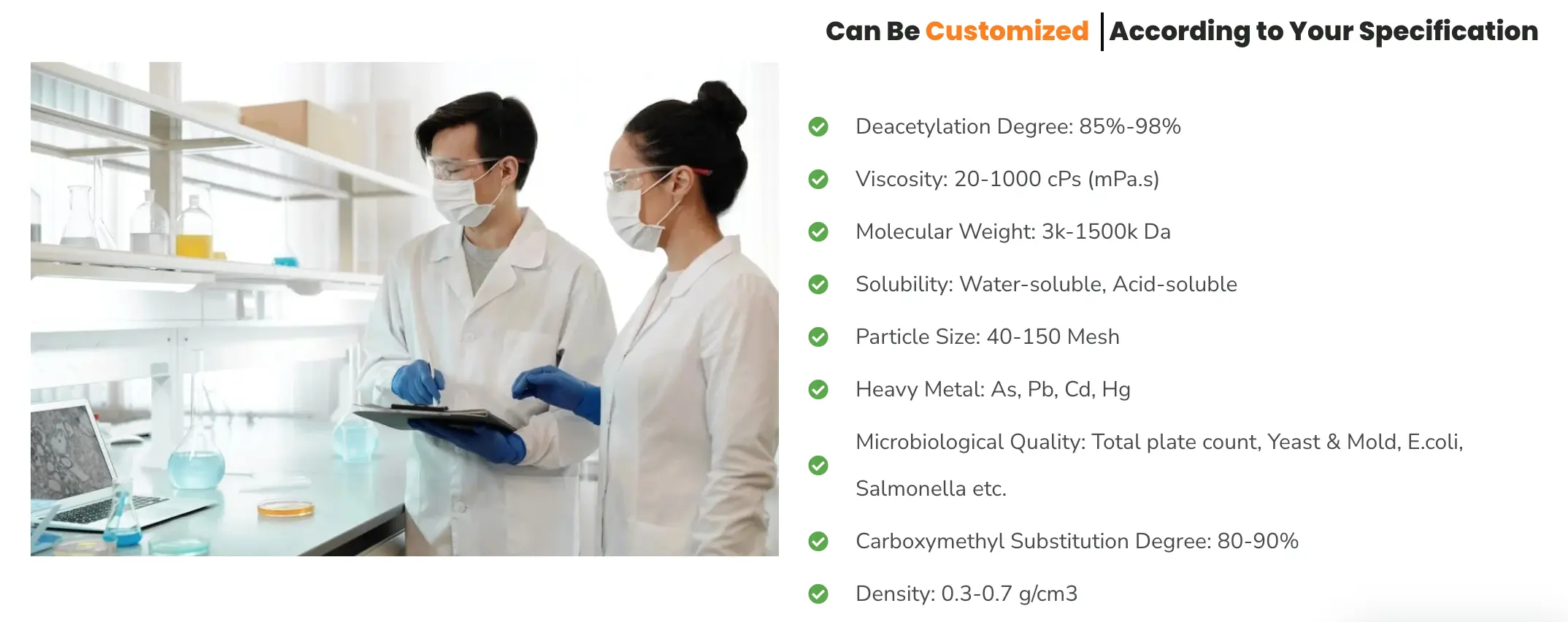

Specification

- Molecular Weight: ≤ 5kDa

- Appearance: Light yellow powder

- Degree of Deacetylation: ≥ 98%

- Solubility: Easily soluble in water solutions

- Moisture Content: ≤ 10%

Solubility

This chitosan oligosaccharide is highly soluble in water, typically at a 1% solubility ratio, maximum 10%-20%, ensuring rapid dissolution and easy integration into various formulations. Its low molecular weight enhances its effectiveness in applications requiring quick absorption and high bioactivity.

Kindly watch the videos of solubility of different types of vegetal chitosan: https://www.chibiotech.com/video/

Specification Customized Service

We offer tailored solutions to adjust the molecular weight, degree of deacetylation, and other specifications to meet your specific application needs, ensuring optimal performance.

Advantages & Benefits

- Enhanced Bioavailability: Low molecular weight allows for rapid absorption and high effectiveness in biological applications.

- Vegan and Non-Allergenic: Safe for vegans and individuals with shellfish allergies, as it is entirely plant-based.

- High Purity: Ensures a clean and effective ingredient free from animal derivatives.

- Eco-Friendly: Produced through sustainable practices, contributing to environmental conservation.

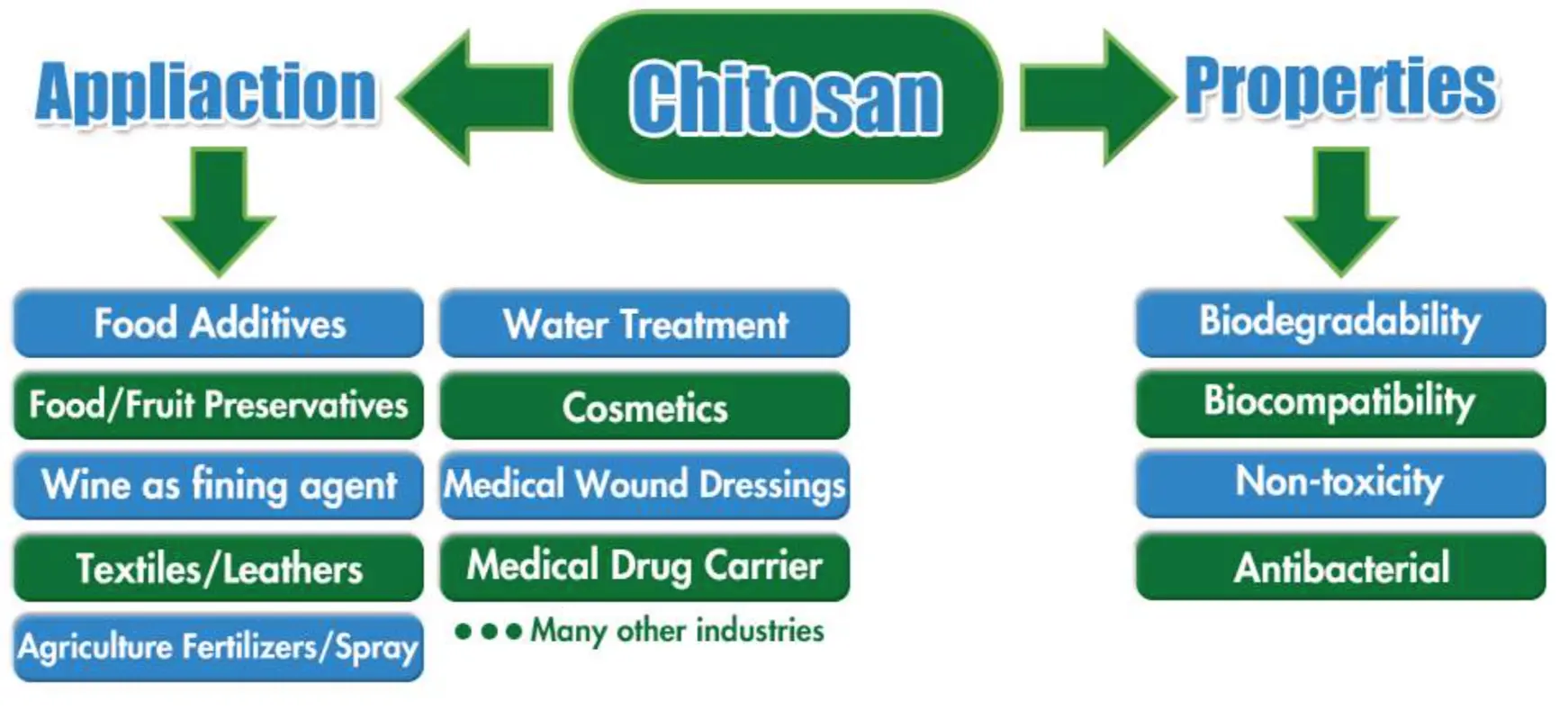

Functions

- Antimicrobial Activity: Inhibits bacterial and fungal growth, enhancing product safety and longevity.

- Immune Boosting: Supports immune function, making it ideal for dietary supplements and health products.

- Biodegradability: Naturally decomposes, reducing environmental impact.

- Plant Growth Stimulant: Enhances plant growth and resilience, making it useful in agriculture.

Main Applications (More about applications)

- Dietary Supplements: Used for its health benefits, particularly in products aimed at immune support and gut health.

- Agriculture: Acts as a bio-stimulant, promoting plant growth and disease resistance.

- Cosmetics: Enhances skin care products with its moisturizing and bioactive properties.

- Food & Beverage: Serves as a natural preservative and functional ingredient in health-focused products.

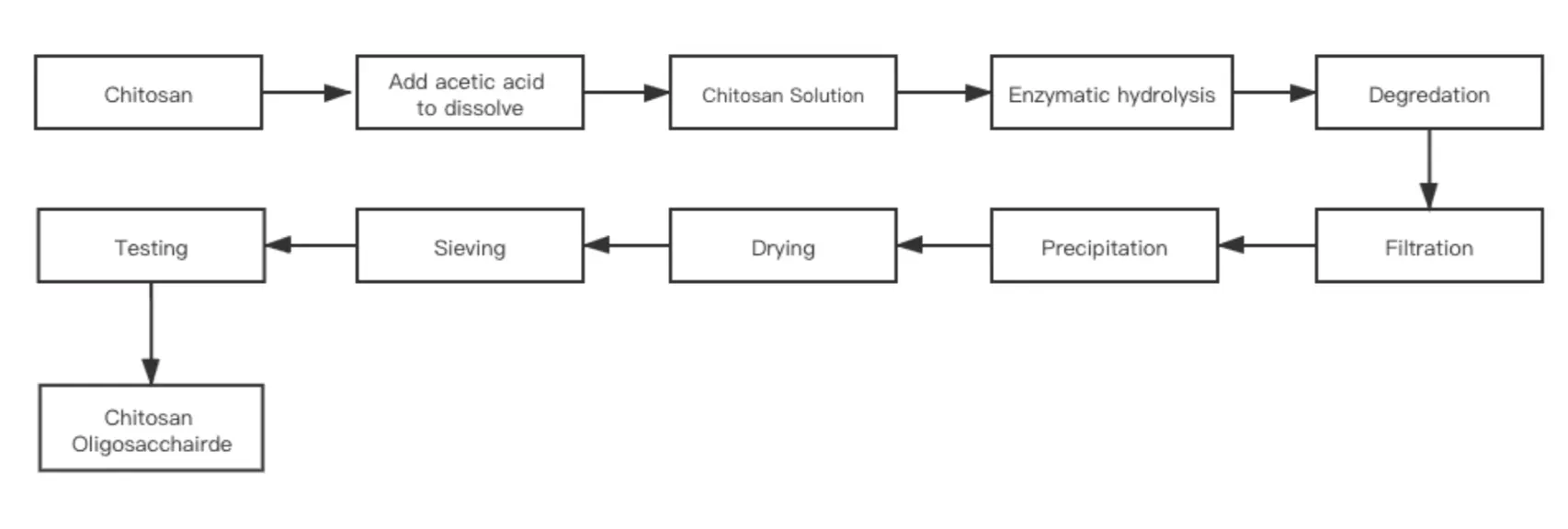

Flowchart

Our production process involves dissolving chitosan in acetic acid, followed by enzymatic hydrolysis, filtration, drying, sieving, and final testing to ensure the highest quality of chitosan oligosaccharide.

The flowchart of oyster mushroom chitosan illustrates the process of producing chitosan and its derivatives from mushroom material. Here’s a summary of the key content:

- Starting Material: The process begins with mushroom material as the source.

- Filtration: The mushroom material undergoes a filtration process.

- Protein Removal: Proteins are then removed from the filtered material using an alkali solution.

- Ash Removal: Ash content is subsequently removed with acid.

- Chitin Extraction:

- Acid is added without bubbles to proceed to the next stage.

- Chitin is extracted, which is not soluble in acid.

- An acetylation step removes the acetyl groups from the chitin using sodium hydroxide (NaOH), converting it into chitosan, which is soluble in acid.

- Drying: The acid-soluble chitosan is then dried to produce the final mushroom chitosan product, showcased as a white powder.

- Chitosan Derivatives: Parallel to the drying process, there is a branch leading to the production of various chitosan derivatives:

- Chitosan Hydrochloride: Chitosan converted into its hydrochloride form.

- Enzyme Hydrolysis: Produces chitosan oligosaccharide through enzymatic hydrolysis.

- Carboxymethyl Chitosan: Derived through the carboxymethylation of chitosan.

The flowchart depicts a methodical approach to converting mushroom material into various forms of chitosan, focusing on the purification and chemical modification steps necessary to achieve different chitosan-based products for use in various applications.

Here are simplified descriptions of the flowcharts for Chitosan Oligosaccharide:

Chitosan Oligosaccharide Production:

- Step 1: Chitosan is dissolved in acetic acid to form a solution.

- Step 2: Enzymatic hydrolysis is applied, followed by degradation.

- Step 3: The solution undergoes filtration and precipitation.

- Step 4: The product is dried, sieved, and tested.

- Result: Chitosan Oligosaccharide.

Why Choose Us? (>>See more about us)

- Expertise: Chibio Biotech has over 8 years of experience in producing high-quality vegetal chitosan, trusted by clients globally.

- Certified Quality: Our products are ISO 22000:2018, Halal, Kosher, and Organic certified, ensuring adherence to the highest industry standards. (>>See more about our certificates)

- Customized Solutions: We provide tailored chitosan solutions to meet your specific needs, ensuring the best performance for your applications.

- Global Reach: Serving customers in over 50 countries, we have the expertise and capacity to support your business wherever you are.

Why your businesses consider using vegetal chitosan?

Using vegetal chitosan in your applications or formulations offers significant benefits to businesses, as outlined below:

- Eco-Friendly and Sustainable: Vegetal chitosan is derived from plant sources such as mushrooms and fungi, making it an environmentally sustainable alternative to traditional animal-based chitosan. This aligns with growing consumer demand for green and eco-friendly products.

- Non-Allergenic and Vegan-Friendly: Unlike crustacean-derived chitosan, vegetal chitosan does not trigger shellfish allergies and is suitable for vegan and vegetarian consumers. This widens the market reach for products formulated with vegetal chitosan.

- Versatility and Superior Functionality: Vegetal chitosan offers excellent biocompatibility, biodegradability, and antimicrobial properties. These attributes enhance its utility across various industries, including food, pharmaceuticals, cosmetics, textiles, and agriculture.

- Enhanced Product Performance: In many applications, vegetal chitosan improves product qualities such as moisture retention, antimicrobial efficacy, and barrier properties. This leads to better-performing end products, such as longer shelf-life for food items or improved durability and functionality in textiles.

- Market Differentiation: Incorporating vegetal chitosan allows companies to differentiate their products by promoting natural, sustainable, and allergen-free claims, which are increasingly valued by health-conscious and environmentally aware consumers.

In summary, using vegetal chitosan can help your businesses enhance their product offerings, meet consumer demands for sustainable and non-allergenic ingredients, and improve your overall market positioning.

Explore the benefits of Water-soluble Oyster Mushroom Chitosan Oligosaccharide today! Contact us for more details or to request a custom quote.

Get in touch with us to boost your business

- Get Free Sample

- Get Step Quote

- 24/7 Service

- Customized Specification

- Confidentiality Agreement

Headquarter

Block B, Vanke Center, No.2 Heilongjiang South Road, Shibei District, Qingdao City, China 266033

Phone

+86 (0)532 66983270

Cellphone / WhatsApp / WeChat

+86 156 6577 2296

+86 133 8100 5417