Nisin

Nisin

Additional information

| Product Name | Nisin (e234) |

|---|---|

| Source | Fermented by strains of Lactococcus lactis subsp lactis |

| Appearance | Light brown to almost white powder |

| Cas No.# | 1414-45-5 |

| Chemical Formula | C143H228N42O37S7 |

| Hydrous Potency | Typical ≥1000 iu/mg, 30000 iu/mg Max |

| Solubility | Soluble in water and acidic solutions |

| Functions | Natural antimicrobial peptide widely used in food preservation to inhibit the growth of Gram-positive bacteria. |

| Main Applications | Food (Daisy, Meat, Canned Food, Beverage, etc.), Pharmaceuticals (Oral care, Wound care), Cosmetics (Skincare, Haircare). |

Product Details

Nisin – A Powerful Natural Antimicrobial Preservative

Nisin is a natural antimicrobial peptide widely used in food preservation to inhibit the growth of Gram-positive bacteria, including foodborne pathogens like Listeria monocytogenes and Clostridium botulinum. This highly effective and natural preservative ensures food safety while extending shelf life, making it an ideal choice for the food, pharmaceutical, and cosmetic industries.

Nisin is a natural antimicrobial peptide widely used in food preservation to inhibit the growth of Gram-positive bacteria, including foodborne pathogens like Listeria monocytogenes and Clostridium botulinum. This highly effective and natural preservative ensures food safety while extending shelf life, making it an ideal choice for the food, pharmaceutical, and cosmetic industries.

What is Nisin (e234)?

Nisin is a bacteriocin, a type of antimicrobial peptide produced by Lactococcus lactis during fermentation. It has been extensively used as a food preservative for decades due to its ability to prevent spoilage and microbial contamination. Approved by global regulatory bodies such as FDA, WHO, and EFSA, Nisin is classified as GRAS (Generally Recognized as Safe) and has an E-number E234 in the European food additive system.

Nisin natural antimicrobial is used to control bacterial spoilage in both heat processed and low pH foods. Nisin is a natural polypeptide antibacterial produced by strains of Lactococcus lactis subsp lactis. Nisin is effective against a wide range of Gram-positive bacteria and is particularly effective against the heat resistant spores produced by Gram-positive Bacillus and Clostridium spp. Nisin has no effect against Gram-negative bacteria, yeasts or moulds.

Nisin is manufactured from the fermentation of a milk-based medium by Lactococcus lactis subsp. lactis. The nisin from this fermentation is concentrated, dried and standardized with sodium chloride to produce Nisin, which has a known and consistent level of nisin activity.

Nisin is soluble in aqueous environments and is most stable to heat in acidic conditions. At typical usage levels, Nisin does no affect the colour or flavour of the finished product.

Source of Nisin

Nisin is naturally derived from Lactococcus lactis, a lactic acid bacterium commonly found in fermented dairy products. The purified form of Nisin is extracted using advanced biotechnology to ensure high purity and effectiveness.

Chemical Information

- CAS Number: 1414-45-5

- Chemical Formula: C143H228N42O37S7

- Hydrous Potency: Typical ≥1000 iu/mg, 30000 iu/mg Max

- Appearance: Light brown to almost white powder

- Solubility: Soluble in water and acidic solutions

- Package: 500g/bottle, 10kg/carton

Nisin Specifications

| Parameter | Specification |

|---|---|

| Hydrous Potency | Typical ≥1000 iu/mg, 30000 iu/mg Max |

| Solubility | Completely soluble in water |

| Sodium Chloride (%/w/w) | Typical ≥50% |

| Loss on drying | ≤3.0% |

| Heavy Metals | ≤10 ppm |

| Lead (Pb) | ≤1 ppm |

| Microbiological quality

Total Plate Count E.coli Salmonella |

≤10 cfu/g ≤3.0 MPN/g Not detected/25g |

Solubility:

Nisin is a light brown solid powder that needs to be dissolved in water or liquid when used, and its solubility is different at different pH values.

For example, in water (pH=7), the solubility is 49.0mg/ml (Nisin); if in 0.02M hydrochloric acid, the solubility is 118.0mg/ml (Nisin); under alkaline conditions, it is almost insoluble.

Stability:

The stability of Nisin is also related to the pH value of the solution. If dissolved in skim milk with pH=6.5, after 85 pasteurization for 15 minutes, the activity only loses 15%.

When dissolved in dilute hydrochloric acid with pH=3, it still maintains 100% activity after 12115 minutes of high-pressure sterilization. It has excellent acid and heat resistance.

Key Advantages & Benefits of Nisin

✅ Natural & Safe – Derived from natural fermentation, Nisin is a non-toxic, biodegradable preservative.

✅ Broad-Spectrum Antimicrobial Activity – Inhibits a wide range of Gram-positive bacteria, including spoilage and pathogenic bacteria like Listeria monocytogenes.

✅ Enhances Food Safety – Effectively prevents foodborne illnesses by controlling bacterial contamination.

✅ Extends Shelf Life – Reduces spoilage, minimizing food waste and increasing product longevity.

✅ Stable at Various pH Levels – Active in acidic environments, making it ideal for dairy, meat, beverages, and canned foods.

✅ Heat-Resistant – Retains efficacy even after pasteurization and high-temperature processing.

✅ Does Not Alter Food Taste or Texture – Works efficiently without compromising food quality.

✅ Approved for Use Globally – Accepted by FDA, EFSA, WHO, and other regulatory authorities.

Functions of Nisin

- Food Preservation – Inhibits spoilage bacteria in dairy, meat, beverages, and ready-to-eat foods.

- Bacterial Control in Pharmaceuticals – Used in topical applications, wound dressings, and oral care products.

- Natural Alternative to Chemical Preservatives – Helps replace artificial preservatives in clean-label formulations.

- Prevents Biofilm Formation – Effective in industrial processing environments for bacterial control.

Applications of Nisin

1. Food Industry

Nisin is effective in a variety of food products across a wide range of PH levels (3.5-8.0), including:

- Dairy: Cheese products: processed cheese and cheese, spreads, club cheese, blended cheese, direct-acidified fresh cheeses, natural ripened cheese; Cream products (flavoured, shipped, thickened, sour cream, etc.); dairy and fat based desserts; yoghourt; recombined and flavoured milks.

- Fruit & vegetable preparations including pulp, pasteurised fruit juices, plant protein based beverages, coconout water.

- Wips and snacks

- Pasteurised liquid egg products

- Low pH sauces and toppings including mayonnaise and salad dressings

- Pasteurised soups and sauces

- Hot plate flour products e.g. crumpets

- Fermentation processes and fermentation products such as beer

- Meat & Poultry: Processed meats, sausages, and canned meats to control bacterial contamination.

- Beverages: Juices, beer, and other low-pH drinks to prevent microbial spoilage.

- Canned & Packaged Foods: Used in canned vegetables, soups, sauces, and ready-to-eat meals for extended shelf life.

- Plant-Based Foods: Ideal for vegan and plant-based food preservation.

2. Pharmaceutical & Healthcare

- Oral Care: Used in toothpaste and mouthwashes for its antibacterial properties.

- Wound Care: Incorporated in bandages and gels for infection prevention.

3. Cosmetics & Personal Care

- Skin Care: Included in lotions and creams to prevent bacterial contamination.

- Hair Care: Used in shampoos and conditioners for antimicrobial benefits.

Usage Levels Recommendation

Recommended addition levels for nisin would typically be between 25-500mg per kg or litre of food. Exact dosage levels will depend on the nature of the food product, processing condition, microbial load and shelf life requirements.

Some loss of nisin activity can be expected during the heat processing of foods with further activity losses during shelf life. These factors are taken into consideration when usage recommendations are made by our Technical Service Team.

Advice should be sought for more precise recommendations on specific usage levels.

|

Applications |

Suggested Dosage Max (Nisin 1000 IU/mg.) |

|

Seafood (vacuum packed) |

1000 mg/kg |

|

Processed cheese |

600 mg/kg |

|

Unripened cheese, Ripened cheese, Whey cheese,Cheese analogues, Whey protein cheese |

200 mg/kg |

|

meats and poultry products |

500 mg/kg |

|

Pasteurized milk products |

400 mg/kg |

|

Fine bakery wares |

250 mg/kg |

|

Canned foods (high acids) |

300 mg/kg |

|

Canned or bottled (pasteurized) or retort pouch vegetables |

200 mg/kg |

|

Egg products |

300 mg/kg |

|

Salad dressing |

200 mg/kg |

|

Pasteurized chilled soups |

200 mg/kg |

|

Fruit juices, Fruit drinks |

150 mg/kg |

|

Beer, Grape wine, Fruit wine |

100 mg/kg |

|

Yoghurt |

50 mg/kg |

|

Clotted cream |

10 mg/kg |

|

Cereal and starch based desserts |

5 mg/kg |

Directions for Use

Nisin should be added to heat processed foods by thorough dispersion in the food substrate prior to the heating process. Nisin can be added directly to the food as either a dry powder or as a pre-suspension in water or milk.

In some processing situations there may be potential for adding Nisin by other methods such as dipping, or alternatively after a fermentation process, e.g. stirred yoghourt. Advice should be sought for these more specialized food application areas.

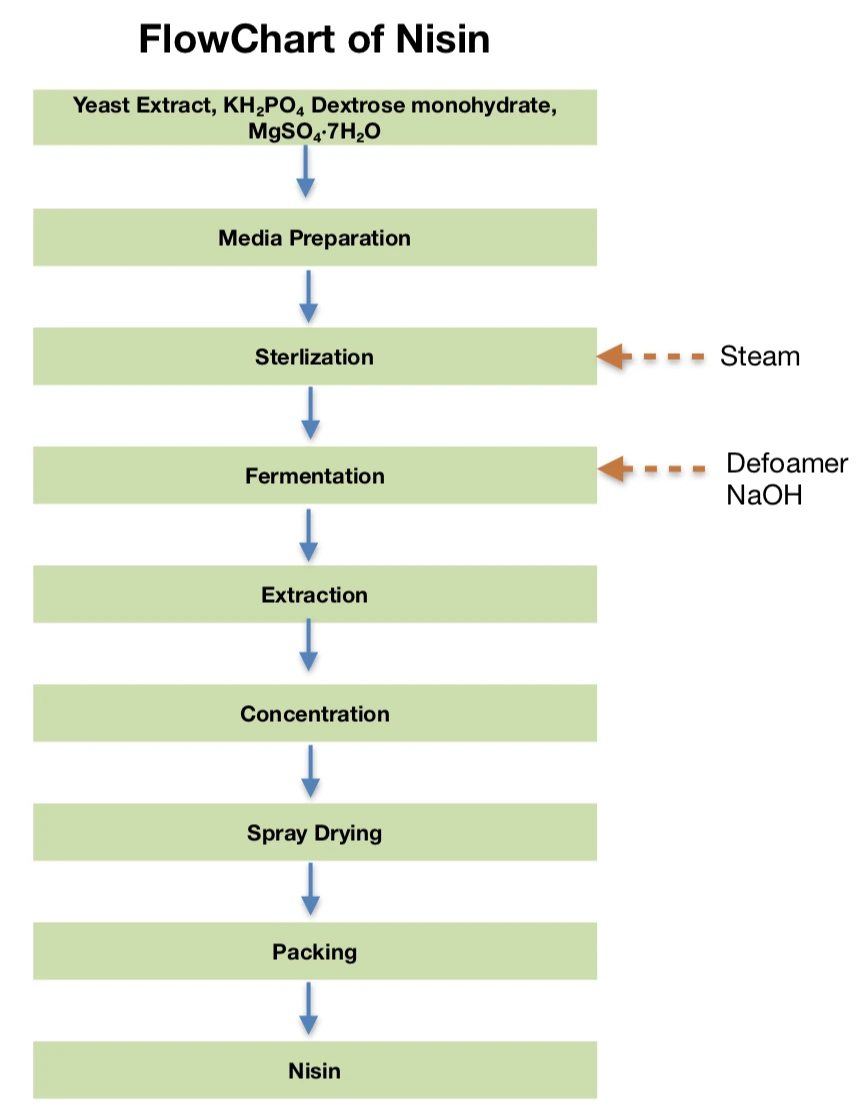

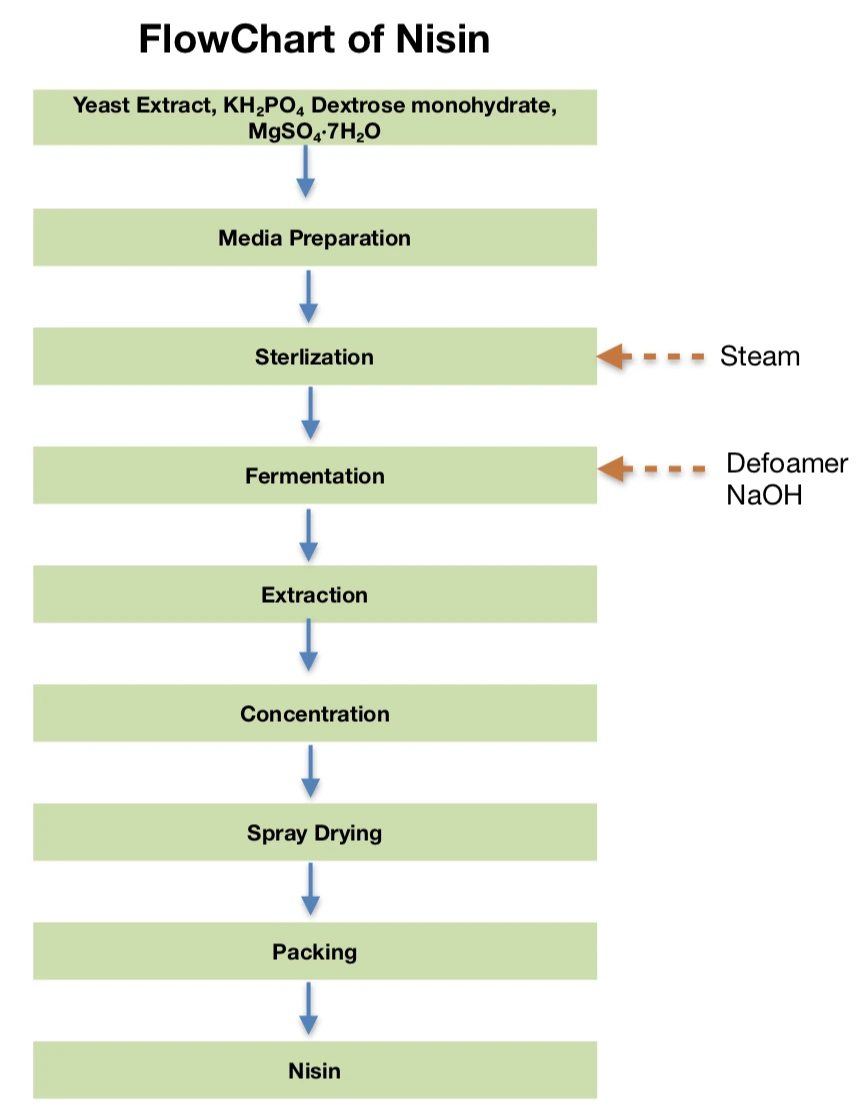

Production Process of Nisin

1️⃣ Raw Materials – Yeast Extract, KH₂PO₄, Dextrose Monohydrate, MgSO₄·7H₂O

2️⃣ Media Preparation

3️⃣ Sterilization (Using Steam)

4️⃣ Fermentation (Addition of Defoamer & NaOH)

5️⃣ Extraction

6️⃣ Concentration

7️⃣ Spray Drying

8️⃣ Packing

9️⃣ Final Product: Nisin

This structured process ensures the production of high-quality Nisin, maintaining its purity and effectiveness as a natural antimicrobial preservative. 🚀

Why Choose Chibio Biotech for Nisin?

🌱 Premium Quality – High-purity Nisin produced using advanced fermentation techniques.

🌎 Global Certifications – Compliant with ISO22000, Kosher, Halal, FDA, and EFSA regulations.

🔬 Strong R&D Capabilities – Continuous innovation in natural preservatives and food safety solutions.

📦 Reliable Supply Chain – Efficient logistics ensure timely delivery worldwide.

💡 Customized Solutions – Tailored Nisin formulations based on specific industry needs.

Why Should Your Business Use Nisin?

🔹 Reduce reliance on artificial preservatives – Meet consumer demand for natural and clean-label food products.

🔹 Improve shelf life & product safety – Minimize food spoilage and enhance product stability.

🔹 Comply with food safety regulations – Stay ahead of global food safety standards.

🔹 Enhance sustainability – Nisin is biodegradable, reducing the environmental impact of synthetic preservatives.

Get in Touch – Inquiry Now!

Interested in using Nisin in your food, pharmaceutical, or cosmetic products?

Contact Chibio Biotech for bulk orders, technical support, and customized solutions.

📩 Email: sales@chibiotech.com

📞 Phone: +86 (0)532 66983270

🌍 Website: www.chibiotech.com

Boost your product safety naturally with Nisin – The Future of Food Preservation!

>More details about Comparison between Nisin & e-Polylysine & Natamycin

Get in touch with us to boost your business

- Get Free Sample

- Get Step Quote

- 24/7 Service

- Customized Specification

- Confidentiality Agreement

Headquarter

Block B, Vanke Center, No.2 Heilongjiang South Road, Shibei District, Qingdao City, China 266033

Phone

+86 (0)532 66983270

Cellphone / WhatsApp / WeChat

+86 156 6577 2296

+86 133 8100 5417